Rheology of Muffin Batters By Line Spread Test and Viscosity Measurements

Sikha Bhaduri1*, Amit Kumar Mukherjee2

1 Department of Nutrition, School of Urban Public Health, Hunter College, NY, USA.

2 Department of Food Technology, Haldia Institute of Technology, Haldia, WB, India.

*Corresponding Author

Sikha Bhaduri, Ph.D,

School of Urban Public Health, Hunter College, NY10035, USA.

Tel: 1-212-396-7789

E-mail: sbhaduri@hunter.cuny.edu

Received: September 05, 2016; Accepted: October 10, 2016; Published: October 13, 2016

Citation: Sikha Bhaduri, Amit Kumar Mukherjee (2016) Rheology of Muffin Batters by Line Spread Test and Viscosity Measurements. Int J Food Sci Nutr Diet. 5(9), 325-329. doi: http://dx.doi.org/10.19070/2326-3350-1600058

Copyright: Sikha Bhaduri© 2016. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

Abstract

This work was aimed to quantify the flow properties of muffin batters by Line Spread Test (LST) and to establish a valid correlation between their line spread distance and viscosity. LST is a quick and inexpensive method for comparing relative viscosities of food slurries or a solid-liquid suspension type of food materials, like muffin batters. The rheological properties of muffin batters formulated using gluten free flours were studied. Five different combinations of rice flour and quinoa flour were studied as gluten free flour combinations. Control muffin batters were formulated using 100% wheat flour, which is a gluten positive flour. Density, pH, line spread distance and viscosity were measured for all six batter formulations including control. All tests were performed in triplicate and all data were analyzed statistically. In general, gluten free flour reduced the density and increased the acidity of muffin batters. Whereas, line spread distance was increased and viscosity was decreased with replacement of quinoa flour to rice flour in the muffin batters. A valid correlation between line spread distance and viscosity was observed. The inverse of LST in cm/sec was observed to be close to the viscosity in poise for muffin batters in this study.

2.Introduction

3.Materials and Methods

3.1.Muffin Formulations

3.2.Studies On Muffin Batters

4.Results and Discussions

4.1.Implication

5.Acknowledgements

6.References

Keywords

Line Spread Test (LST); Viscosity; Flow Properties; Muffin Batters; Solid-Liquid Suspension; Food Slurry.

Introduction

Rheology is the study of the flow properties of liquid materials, which concerns the flow and deformation of matter [1]. Viscosity is a rheological property of fluids, which quantitates the fluid’s resistance to flow. Fluid has a natural tendency to be deformed by internal friction, known as shear stress of its layers. Viscosity is that force which resists this deformation. A liquid's viscosity depends on the size and shape of its particles and the attractions between the particles. A fluid that has no resistance to shear stress is known as an ideal fluid or inviscid fluid. A liquid whose viscosity is less than that of water is known as a mobile liquid, while a substance with a viscosity substantially greater than water is called a viscous liquid. Many foods are complex materials possessing characteristics of both liquids and of elastic solids. Such materials are termed as viscoelastic [2]. Viscoelastic materials are described by the properties such as viscosity and elastic moduli. Although viscoelastic properties have been used to describe foodstuffs, no specific analytical methods have yet been applied either for standardizing thickened liquid preparations or for understanding the effect of material property variations on the swallowing system. Different professionals for example speech pathologists, dietitians, food service managers, and dysphagic food manufacturers determine and standardize their own individual dietary consistencies, which depend on their own understanding and specific needs and practice [3, 4].

It is, however, important to note that, the basic knowledge on mechanics is necessary to interpret data from rheological testing. Higher equipment costs makes such instrumental techniques impractical for dietitians and other professionals. Food slurries are thickened liquids and possess viscoelastic properties [5]. The main factors for determining the slurry viscosity are particle concentration, particle size, particle size distribution and shape in the thickened liquid. These, on the other hand, depend on the solid and the liquid compositions of the thickened liquid. Batters are widely diffused liquid-like viscoelastic materials used for the production of numerous baked cereal foods. Muffin is a popular breakfast snack food and the quality of a good muffin depends on its batter composition. A perfect batter composition gives a good taste and soft texture to a quality muffin which is highly appreciated by consumers. In other words dough rheology plays a key role in making baked snack foods. Therefore this is very important to study the viscosity of the muffin batters. Muffin batters are food slurry whose viscoelastic properties are dependent mainly on its flour composition, since flour is the major constituent of a muffin batter.

Standard laboratory measurements of viscosity normally use a viscometer operating at a controlled temperature and shear rate. Although, the viscometer accurately measures viscosity of a liquid, they are expensive and also are not always available. The other difficulty relating to the knowledge in mechanics has already been stated earlier. To overcome such shortcomings, a Line Spread Test (LST) has been suggested as an alternative [6]. The LST is designated as and suggested to be a simpler and practical alternative to the more complex instruments used for characterizing thickened liquids like muffin batters [7].

The LST was developed in the 1940s [8, 9] for quantifying the consistency of liquid-like foods (the original device was termed as the ‘‘consistometer’’ and was developed for creamed corn). This instrument quantifies the consistency of a liquid using the distance upto which a standard amount is spread on a horizontal surface after being released from a confined chamber. The LST does not represent the viscosity in general. It is rather is a quick and inexpensive method to determine the flow behaviors of solid-liquid suspension type of food materials. The muffin batters are complex systems of solid-liquid suspensions whose rheological properties depend on the solid-liquid composition. However, there have been only a limited number of studies on the fundamental rheological properties of batters [11]. Viscosity is an important rheological property of muffin batters, which determine muffins taste, texture and consumer acceptability at the end. Conceptually, the more viscous materials should have lesser Line spread capabilities. Hence, it is assumed that the approximate viscosities of muffin batters can be calculated by Line spread test. Therefore the objective of the present study was to determine the rheological behavior of muffin batter using total six different flour formulations by both viscosity and Line spread test measurement and to investigate and establish a valid correlation between these two experimental data.

Methods

Modified muffin recipe [11, 12] contained white sugar, baking powder, pure canola oil, 2% reduced fat milk and egg, besides flour, as described in Table 1. Whole wheat flour, white rice flour and quinoa flour were used as different flour replacement to prepare muffin batters. Total 6 formulations were tried in terms of flour compositions and they were 100% Wheat flour, 100% Rice flour, 75% Rice flour + 25% Quinoa flour, 50% Rice flour + 50% Quinoa flour, 25% Rice flour + 75% Quinoa flour and 100% Quinoa flour. Flour, sucrose, baking powder, and salt were mixed together in a separate bowl, and then were sifted into with the wet ingredients at speed 4 for 10 seconds to prepare the muffin batter.

Specific gravity of muffin batters (at 21.8 ± 2°C) was measured by using a pycnometer (Fisher Scientific, Pittsburg, PA) and was determined by dividing the weight of a standard measure of the batter by the weight of an equal volume of water. Batter density was calculated by dividing the sp gravity of batter with specific gravity of water at the corresponding temperature (21.8 ± 2°C). Three replicates for each variation were measured.

The pH of muffins were measured with a bench top conductivity/pH meter (Model 1671, Jenco Electronics Ltd., Taiwan) at a 1 : 10 (w/w) dilution in de-ionized water.

The viscosity of muffin batter was determined [13] using Brookfield DV-II + Pro Viscometer (Middleboro, MA). 500 mL Muffin batter was transferred into a 600-mL Beaker. The angular speed, torque and apparent viscosity were read directly from the equipment display The spindle speed was set to 5 rpm, and spindle no. 4 (S64) was used for all the experiments, as per Company’s instruction. The experiment was run at room temperature (21.8 ± 2°C). Viscosity was measured immediately after preparation of muffin batters. All tests were performed in triplicate.

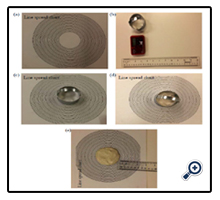

Line spread test for muffin batters were performed using a line spread chart. A typical Line spread chart and step by step description of line spread test is shown in Figure 1. This is a simple variation of the measurement of viscosity by consistometers. Line spread chart is a sheet of paper (8.5 x 11 inches or 215.9 X 279.4 millimeters), which contains concentric circles with quartered regions evenly measured off. A small metal cylinder of 1.5 to 2 inches (38.1 to 50.8 millimeters) in height corresponds in circumference with the smallest of the concentric circles on the paper. Other pieces of equipment in this test include a glass plate which is at least as wide and long as the largest of the concentric circles, to place the Line spread chart on it and a stop watch to record time intervals. The line spread chart was laminated with a washable plastic cover which eliminates the use of glass plates. A measured amount of sample (1/4 Cup = 60 milliliters) is placed in the metal cylinder centered on the line spread chart of measured, concentric rings and is allowed to flow for a measured length of time (upto 10 minutes), after which the spread is read quickly at four equally spaced axes. The mean of the four values obtained is the average line spread (unit: millimeters) that the material spreads in 10 minutes. Three replications for each variation were tried.

Triplicate measurements for each formulation were conducted. Statistical analysis was performed for all experimental data using Microsoft excel. All the results were expressed as mean ± SD (Standard Deviation) and P-values of <0.05 were considered significant.

Results and Discussions

The experimental data on the physical characteristics of different muffin batters are represented in the Table 2. Density (gm/cm3), viscosity (cp), LST value (mm/10min) and pH of muffin batter were tabulated in this Table. Wheat flour is known to be gluten positive flour while rice flour and quinoa flours are both gluten free flours. Incorporation of gluten free flours decreases both the density (from 1.34 ± 0.03 gm/cm3 to 1.09 ± 0.01 gm/cm3) and pH of muffin batters (from 7 ± 0.25 to 6.5 ± 0.1) as indicated in Table 2.

Viscosity values have been affected by sample composition and viscosity would also be strongly dependent on water content, because water acts as a plasticizing agent [14]. Batter viscosity is an important physical property as it is closely related to the final quality of a baked product. A good quality muffin should be a uniformly aerated baked product. Air incorporation, retention, bubble stability and the generation of convection currents during baking are closely related to initial batter viscosity. Batter viscosity is dependent on shear thinning and shear thickening behavior of different flour formulations. Higher water binding capacity for wheat flour produces highly viscous batters. Therefore, 134000 ± 7.07 centipoise was observed as the highest viscosity for wheat flour batters compared to all other gluten free flour formulated batters and lowest value was observed as 31116 ± 6.52 centipoise for 100% rice flour formulated batters. Higher viscosity means lower line spread capability. Therefore, Batter made up with 100% wheat flour had the highest viscosity (134000 ± 7.07 centipoise), lowest LST value (4.47 ± 0.21 mm/10minutes) and highest density (1.34 ± 0.03) compared to others. The higher the Viscosity, the lower will be the LST value, as shown in Table 2. Batter viscosity depends on the water binding capacity of the flours, which is related to its specific gravity also. Dough Rheology plays a key role in baking and some of the factors affect dough rheology is water content, temperature, and protein variety of batter affects dough rheology [15].

The highly hydrophilic characteristics of different flours may decrease water availability and this knowledge could be helpful in the development of new batter formulations. Quinoa flour has a higher water binding capacity, which increases specific gravity of the corresponding muffin batters. Shear thickening property of muffin batters increases with quinoa flour concentration, which is evident from the increase in viscosity of the batter in the present study.

Since the higher the viscosity the lower will be the spreading capability, as a general theory of LST, the inverse of LST values should be comparable to viscosities, as represented in Table 3. The viscosity value in poise is observed to be equivalent to the inverse of LST values in cm/sec, for muffin batters as observed in Table 3. Muffin batters are complex viscous fluids containing solid materials mixed with liquids, whose viscosities depend on solid particle sizes and its water absorbing capacities which varies with time and changes its viscoelastic behaviors. Therefore both the line spread test and viscosity should be measured immediately after preparation of muffin batters. Also, different Food materials have their own flow behaviors depending particularly on its particle size and hydrophilic/hydrophobic abilities, therefore, the relation in Table 3 between viscosities (p) vs. inverse of LST (cm/sec) might be true only for muffin batters not for all other type of food materials. More experimental studies needed to be done with other food components to obtain a generalized formulation. But despite of all these limitations, we can conclude that for muffin batters the line spread distance (in centimeter) and viscosity (in poise) are statistically correlated to each other with a great degree of accuracy and which implies Line spread test shows apparent viscosities of muffin batters.

The line-spread test is a reliable and practically valid alternative tool to assess viscosity of muffin batters because of its ease of usefulness. Since the line-spread test is based on the measurement of product dispersion over a flat surface, the test is also economically adaptable easily by dietary experiments for quality control and also for a preliminary laboratory study, since this test does not require any expensive tools. And therefore, this correlation between LST and viscosity values for muffin batters might be helpful to obtain an approximate idea to get apparent viscosities of muffin batters by its line spread test values for preliminary studies and quality control in dietary experiments.

Acknowledgments

The work was supported by PSC-CUNY-TRADA-43 grant.

References

- Schowalter WR (1978) Mechanics of Non-Newtonian Fluids. Pergamon Press, Oxford- Frankfurt.

- Nicosia MA, Robbins JA (2007) The Usefulness of the Line Spread Test as a Measure of Liquid Consistency. Dysphagia. 22(4): 306-311.

- Pelletier CA (1997) A comparison of consistency and taste of five commercial thickeners. Dyphagia. 12: 74–78.

- Glassburn D, Deem J (1998) Thickener viscosity in dysphagia management: Variability among speech-language pathologists. Dysphagia. 13(4): 218–222.

- Martinez-Padilla, L.P. Food Suspensions and Food Engineering (2005) Food Engineering-Vol II 3.4:1-338.

- Paik N-J, Han TR, Park JW, Lee EK, Park MS, et al., (2004) Categorization of dysphagia diets with the line spread test. Arch Phys Med Rehabil.85(5): 857-861.

- Mann L, Wong K (1996) Development of an objective method for assessing viscosity of formulated foods and beverages for the dysphagic diet. J Am Diet Assoc. 96(6): 585–588.

- Adams MC, Birdsall EL (1946) New consistometer measures corn consistency. Food Industries. 18: 78–80.

- Grawemeyer EA, Pfund MC (1943) Line spread as an objective test for consistency. J Food Sci. 8(2): 105–108.

- Jun X, Michael N (2007) Rheological properties of batter systems containing different combinations of flours and hydrocolloids. J Sci Food Agric. 87(7): 1292–1300.

- Acosta K, Cavender G, Kerr W (2011) Sensory and physical properties of muffins made with waxy whole wheat flour. J Food Quality . 34(5): 343–351.

- Johnson FCS (1988) Utilization of American-produced rice in muffins for gluten-sensitive individuals. Fam Consum Sci Res J. 17(2): 175-183.

- Kim CS, Walker CE (1992) Interaction between starches, sugars and emulsifiers in high-ratio cake model systems. Cereal Chem. 69(2): 206-212.

- Roura SI, Del Valle CE, Aguero La, Davidovich LA (2007) Changes in apparent viscosity and vitamin c retention during thermal treatment of butternut squash (cucurbita moschata duch) pulp: effect of ripening stage. J of Food Quality. 30(4): 538-551.

- Dhanasekharan M, Huang Ha, Kokinp JL (1999) Comparison of observed rheological properties of hard wheat flour dough with predictions of the giesekus-leonov, white-metzner and phan-thien tanner models. J Texture Studies 30(6): 603-623.