Comparison of Lactate Dehydrogenase (LDH), Aspartate Aminotransferase (AST) and Alkaline Phosphatase (ALP) in Saliva of Normal, Gingivitis and Periodontitis Patients

Rafaela Cristiane Canavezi1, Viviane Maria Gonçalves de Figueiredo2, Alecsandro Moura de Silva3, Laura Souto Soares Lepesqueur4, José Renato Cavalcanti Queiroz5, Marcos Massi6, Renata Falchete do Prado7*, Lafayette Nogueira Junior8

1 Department of Dental Materials and Prosthodontics, Institute of Science and Technology of São José dos Campos, São Paulo State University (UNESP),

Sao Jose dos Campos, 12245000 Brazil.

2 Department of Dental Materials and Prosthodontics, Institute of Science and Technology of São José dos Campos, São Paulo State University (UNESP),

Sao Jose dos Campos12245000, Brazil.

3 Department of Dentistry, UNITAU - University of Taubaté, Taubaté, SP, Brazil.

4 Department of Dental Materials and Prosthodontics, Institute of Science and Technology of São José dos Campos, São Paulo State University (UNESP),

Sao Jose dos Campos 12245000, Brazil.

5 Department of Biotechnology, UnP – Laureate University, Natal, 59010020 Brazil.

6 Mackenzie Presbyterian University, School of Engineering-PPGEMN, São Paulo 01302907 Brazil.

7 Department of Dental Materials and Prosthodontics, Institute of Science and Technology of São José dos Campos, São Paulo State University (UNESP),

Sao Jose dos Campos, 12245000 Brazil.

8 Department of Dental Materials and Prosthodontics, Institute of Science and Technology of São José dos Campos, São Paulo State University (UNESP),

Sao Jose dos Campos, 12245000 Brazil.

*Corresponding Author

Renata Falchete do Prado,

Department of Dental Materials and Prosthodontics, Institute of Science and Technology of São José dos Campos, São Paulo State University (UNESP), Sao Jose dos Campos,

12245000 Brazil.

Tel: +551239479036

Fax: +551239479010

E-mail: renatafalchete@hotmail.com

Received: Ocotber 20, 2021; Accepted: November 13, 2021; Published: November 29, 2021

Citation: Rafaela Cristiane Canavezi, Viviane Maria Gonçalves de Figueiredo, Alecsandro Moura de Silva, Laura Souto Soares Lepesqueur, José Renato Cavalcanti Queiroz, Marcos Massi, Renata Falchete do Prado, Lafayette Nogueira Junior. Diamond-Like-Carbon Coating Over Prosthetic Screws: Analysis Of The Torque Maintenance After Retorque. Int J Dentistry Oral Sci. 2021;8(11):5157-5163. doi: dx.doi.org/10.19070/2377-8075-210001036

Copyright: Renata Falchete do Pradol©2021. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

Abstract

Background: The retorqueing of fixing screws has become a routine in clinical practice, aiming to reduce the risk of screw

loosening; however, there are not in vitro studies that evaluate the effect of this clinical practice in nanofilm-coated screws.

The objective of this study was to verify the torque maintenance of prosthetic pillar screws coated with diamond-doped

diamond-like nanofilm (DD-DLC), submitted to retorque, after mechanical fatigue, in external (EH) and internal hexagonal

connections (IH).

Materials and Methods: Different implants and treatments of the prosthetic screws resulted in eight experimental groups

(n=5): untreated and not submitted to fatigue (EH-CON) (IH-CON); untreated and fatigued control (EH-F) (IH-F); with

DLC nanofilm and fatigued (EH-DLCF) (IH-DLCF) and with DD-DLC nanofilm and fatigued (EH-DD-DLCF) (IH-DDDCLF).

The coatings were plasma-deposited through the Plasma Enhanced Chemical Vapor Deposition method. The samples

were exposed to one million fatigue cycles; samples were submitted to reverse torque; samples were retorqued; then samples

were re-submitted to another one million mechanical cycles. After fatigue, the reverse torque of the screws was performed

to determine the torque maintenance. The screws were qualitatively analyzed through a scanning electron microscope. The

statistical analysis used ANOVA.

Results: There was no interaction between the studied factors. The treatment of screws and connection type did not present

significant differences. The coatings did not interfere in the adaptation of the screw to the implant.

Conclusion: The prosthetic screws with DLC and DD-DLC nanofilms, after retorque, did not present increased torque

maintenance.

2.Introduction

3.Materials and Methods

3.Results

4.Discussion

5.Conclusion

5.References

Keywords

Dental Implant; Screw Loosening; Reverse Torque; Retorque; Diamond-Like Carbon Coating.

Introduction

The complications of prostheses over implants present biological

and mechanical levels. Among the mechanical complications, the

loosening and fracture of the prosthetic screw, abutment fracture,

retention loss, crown cementation loss, and implant fracture may

be listed [1]. The screw loosening is the most common mechanical

cause associated with the failure of prostheses over implants

[2]. The adaptation between the abutment and the implant, the

parafunction, and/or oblique loads interfere in the screwed junction

resistance [3], and the corrosion also may interfere in this

issue [4].

In an attempt to minimize or control loosening, new implant, and

pillars designs, and screws surface treatments have been proposed

[5]. The prosthetic screw surface and material composition promote

changes in the coefficient of friction, to which the preload

value is inversely proportional [6].

The coating of the screw threads, as proposed in some studies, is

based on the principle of change in the coefficient of friction of

this surface (dry lubrication) [7], which improves its tribological

properties, generating more longitudinal stability in the pillar-implant

system with less screw loosening incidence [8]. Such coating

has been especially applied as carbon-like diamond (DLC) films,

grown from plasma [9].

An investigation using DCL-coated screws in hexagonal connections,

after fatigue simulation, demonstrated that samples with the

DLC coating were more resistant to an applied force than those

without the coating [7] and presented better torque maintenance

values than the ones with other coatings [10]. The DLC coating

of titanium screws in internal and external hexagonal connections,

after mechanical fatigue, had not shown damage to screws

threads [6].

Another class of carbon-based nanofilms is based on nanocrystalline

diamond [11]. A mixture of nanodiamond nanoparticles

with different forms of sp2-bonded carbon has been used for

improved tribological properties of industrial oils and greases.

These nanodiamond nanoparticles may be used as additives to

lubricants. They are one of the most promising nanocolloidal additives

[12].

Previous studies have shown that the retorquing, 10 min. after

first torque, caused an insignificant maladjustment effect of titanium

screws, suggesting that this procedure could be used routinely

[13]. The retorque evaluation of titanium and gold screws

in six months to one year of fatigue process proved that the titanium

screws stability was greater than the gold screws and after

one year, titanium screws were less stable due to torque loss

when maladjustments were found [14]. After mechanical cycling,

retorque did not present a significant difference between adapted

and non-adapted prostheses; hence, the retorque of gold and titanium

screws is indicated for multiple prostheses, since there was a

reduction in the loosening of such screws [15].

The purpose of this study was to evaluate the torque maintenance

of prosthetic pillar screws coated with diamond-dopped DLC nanofilm

after mechanical fatigue, submitted to retorque in external

(EH) and internal hexagonal connections (IH).

The considered null hypotheses were the following: H01 - The

torque maintenance of nanofilm-treated screws will not present

superior values than the ones of uncoated/non-fatigued screws;

H02 - internal hexagonal connections will not present torque

maintenance values higher than the ones found on external hexagonal

connections, and H03 – diamond-dopped DLC nanofilm

will not present difference in torque maintenance values when

compared to DLC nanofilm.

Materials And Methods

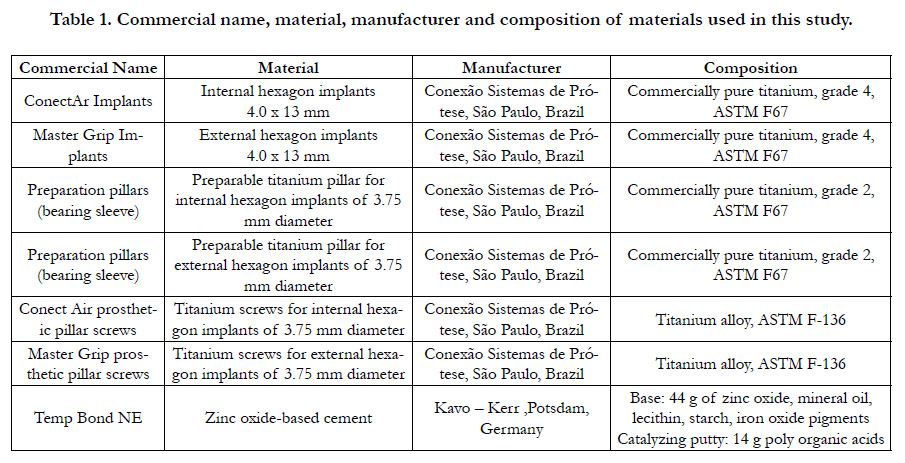

Material

The materials used in this research are listed in Table 1.

Experimental and Sample Groups

This study was performed with the following experimental groups:

EH-CON: Prosthetic pillar screws, EH connection, non-fatigued, untreated.

EH-CONF: Prosthetic pillar screws, EH connection, fatigued,

untreated.

EH-DLCF: Prosthetic pillar screws, EH connection, fatigued,

pre-treated with DLC nanofilm.

EH-DD-DLCF: Prosthetic pillar screws, EH connection, fatigued,

pre-treated with diamond-doped DLC nanofilm (DDDLC).

IH-CON: Prosthetic pillar screws, IH connection, non-fatigued,

untreated.

IH-CONF: Prosthetic pillar screws, IH connection, fatigued, untreated.

IH-DLCF: Prosthetic pillar screws, IH connection, fatigued, pretreated

with DLC nanofilm.

IH-DD-DLCF: Prosthetic pillar screws, IH connection, fatigued,

pre-treated with DD-DLC nanofilm.

For the IH-CON and EH-CON groups, new, non-fatigued screws

were used. Each experimental group had five specimens. The

sampling calculation was performed based on the standard deviation

of a similar study [6], using a data analysis statistics software

(Minitab version 1.6, for Windows, Pennsylvania, USA), with 80%

of sampling power.

Preparation of specimens

The implants were installed in polyurethane resin blocks (22 x

15 mm - Polyurethane F16 with mineral load (RZ 30150-Axson,

France - elastic modulus of 3.6 GPa.). Implants were milled at an

inclination of 90º and installed with the assistance of a manual

ratchet, while blocks were fixed. The applied torque for the installation

of implants was 45 N. 3 mm of the implant threads were

left exposed (ISO 14801), whereas the pillar had a standard height

of 8 mm.

The screws were coated through the Plasma-Enhanced Chemical

Vapor Deposition technique (PECVD). For the DLC and diamond-

doped DCL nanofilms, the gas was the hexane (C6H14)

and the hexane with diamond nanoparticles (2 g/L), respectively.

In this deposition process, the screws were positioned at a sample

holder, which assured proper positioning. The deposition was

performed as previously described [6].

After deposition, screws were torqued with a digital torque meter

(TQ-680, Instrutherm Measuring Instruments São Paulo Brazil).

The torque of 20 Ncm was performed in IH and the torque of

30 Ncm was performed in EH, according to manufacturer recommendation.

Ten minutes after the application of the initial torque,

the procedure was repeated.

Experimental crown

Nickel-chrome alloy total crowns (Litecast B Will-Ceram/USA)

were prepared in a conical-trunk shape, with a diameter and occlusal

height of 8 mm, and presented a hole to access the screw.

The crowns were cemented with zinc oxide cement (Temp Bond

NE, KaVo-Kerr), with 500 g of pressure, for 10 min.

Fatigue testing

Mechanical fatigue was performed through a fatigue simulator

(ER-11000-Erios Plus, Equipment Technical and Scientific São

Paulo, Brazil). Cycles were applied with an average force of 133

N, at eccentric contact (3 mm), frequency of 4 Hz, 1 x106 cycles.

These cycles represent approximately 12 months of function and

were replicated at a temperature of 37°C ± 2°C.

After mechanical cycling, the abutment screw was subjected to

reverse torque (data reported elsewhere [6]).

Retorque and Fatigue testing

Screws were torqued again with the same digital torque meter using

20 Ncm (IH) and 30 Ncm (EH).

Mechanical fatigue was repeated. At the end of fatigue, the screws

were submitted to reverse torque to check the maintenance of

the torque.

Torque maintenance

The remaining torque quantity in each tightened union was calculated,

and these measurements were performed with the digital

torque meter. The reverse torque values were converted into

percentages related to the applied torque (retorque), through the

following equation (1):

Reverse torque (%) = (Reverse torque pos - loading / Applied

torque) x 100

Qualitative analysis

Screws from each group were selected for analysis through a

scanning electron microscope (SEM JEOL, model JSM-5310,

Munich, Germany), for the investigation of eventual alterations

in the structure of the screw (threads). One specimen of each

experimental group was sectioned with a precision cutter (IsoMet

1000, Buehler Ltd. IL, USA) on its longitudinal axis, allowing

observation of the marginal adaptation of the prosthetic screw.

The marginal adaptation was investigated by observing the gap

between the screw and the implant using photomicrographs.

Statistical Analysis

The reverse torque averages (%) of each experimental group were

submitted to statistical analysis using two-way ANOVA (factors:

connections and screws coatings), using Minitab software (version

16.1 for Windows, Pennsylvania, USA) (5% of significance

level).

Data normality was accessed through the Kolmogorov-Smirnov

Test (KS) for each experimental group. This confirms the possible

utilization of parametric statistical analysis, as well as per data

dispersion graphs.

Results

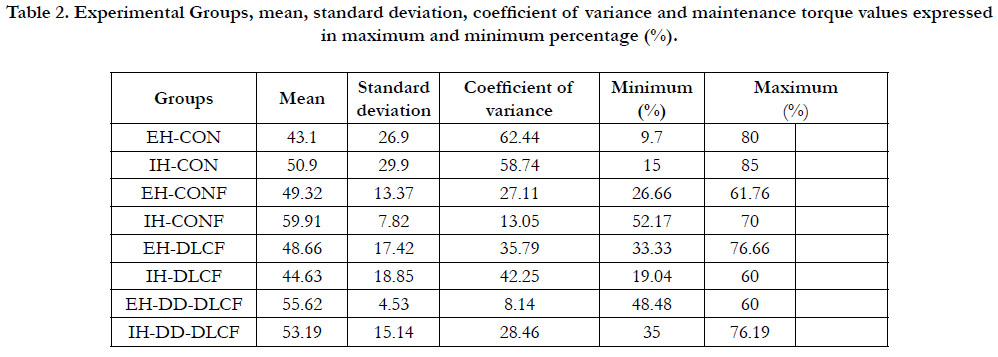

Torque maintenance

All groups presented Gaussian distribution according to the

normality test. There was no significant interaction between the

analyzed factors (screws coatings, p=0.638; implant connections,

p=0.615), nor amongst associated factors (p=0.765). And such findings were repeated between only fatigued groups (screws

coatings, p=0.356; implant connections, p=0.788; associated factors,

p= 0.444). The Group IH-CONF presented the highest

torque maintenance value, followed by EH-DD-DLCF and IHDLCF

(Table 2).

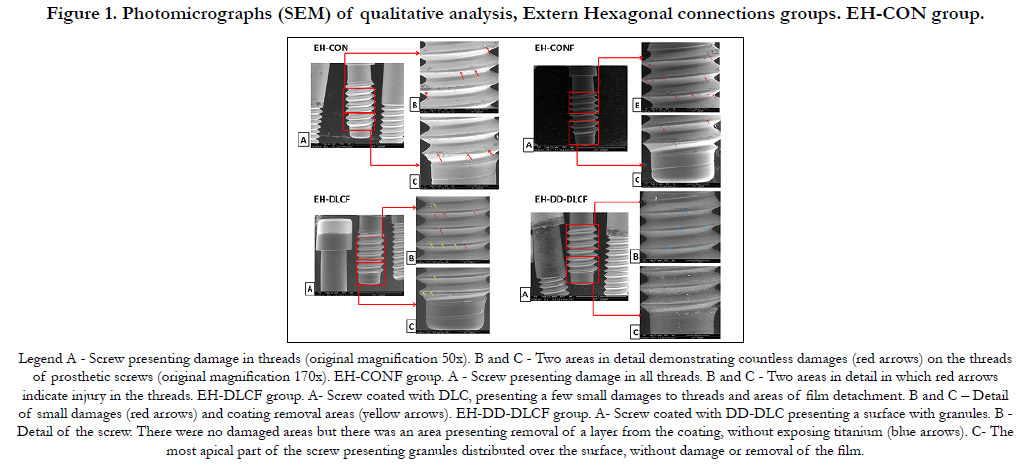

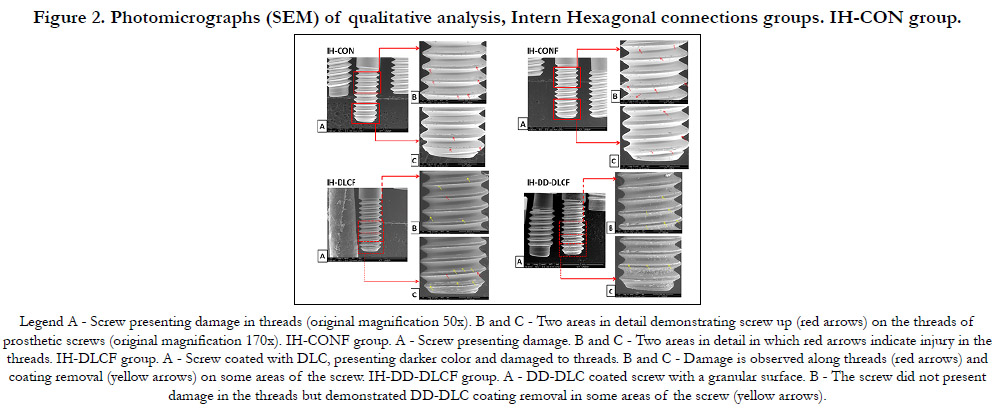

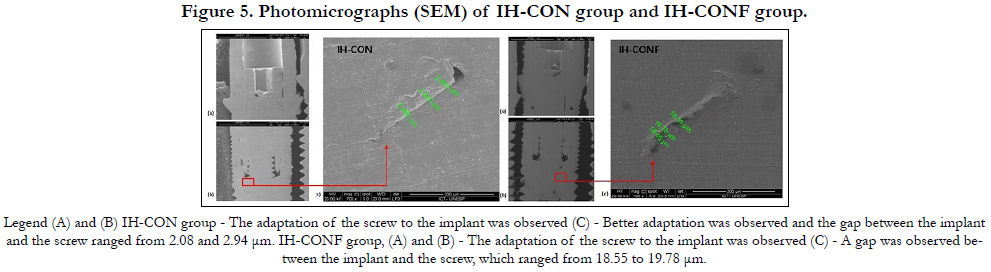

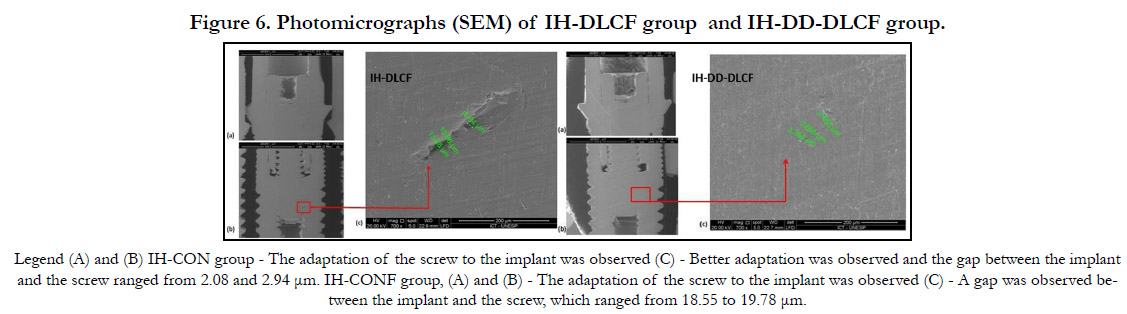

Qualitative analysis: Surface qualitative analysis

In the qualitative analysis of screws, in the EH/IH-DLCF group

(Fig. 1 and 2), there were lower screw thread damages when compared

to the groups without nanofilm.

The EH/IH-CON and EH/IH-CONF groups presented numerous

damages to screws threads (Fig. 1 and 2). The damages

found on EH/IH CON presented larger dimensions, whereas the

damages found in EH/IH-CONF presented higher quantity, but

smaller dimensions.

In some areas, the DLC nanofilm was removed in the EH-DLCF

group (Fig. 1) and IH-DLCF group (Fig. 2). The EH/IH-DDDLCF

groups presented scattered granulation along the screws’

surfaces and no alterations were observed (damage to threads) in

the screw’s structures (Fig. 1 and 2).

In the EH-DD-DLCF group (Fig. 1), the cervical portion of the

screw presented regions of possible coating layer removal, although

no titanium exposure occurred.

In the IH-DLCF group (Fig. 2), there was more incidence of

nanofilm delamination (exposing the titanium) when compared

to the EH-DLCF group (Fig. 1). In the IH-DD-DLCF group,

screws presented areas in which the DD-DLC film was removed

(Fig. 2). For both connections, the cervical portion of screws presented

a smaller quantity of scattered granulation than the apical

portion (Fig. 1 and 2).

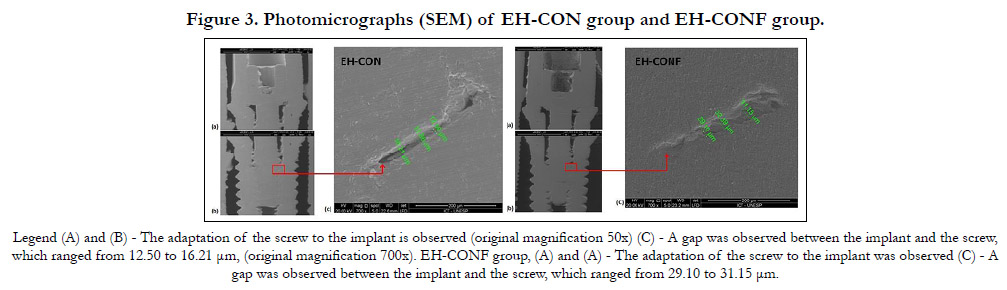

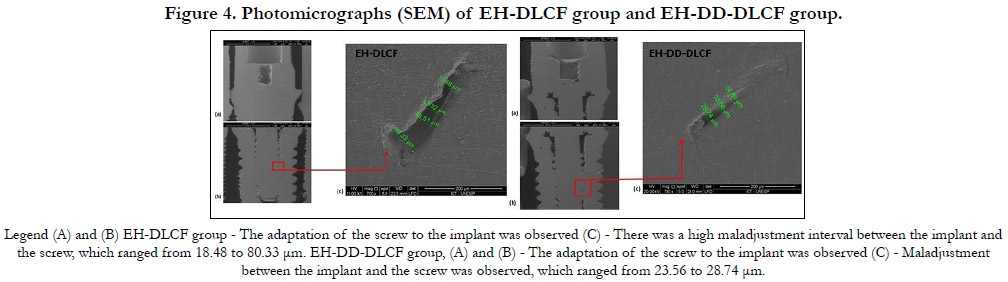

Qualitative analysis: Connection analysis

The DLC and DD-DCL coatings did not interfere in the adaptation

of the screw to the implant (Fig. 3-6). In the connections,

more alterations were observed in EH groups when compared to

IH groups, regardless of screw surface treatment (Fig. 3-6).

For cycled groups, the maladjustments were demonstrated more

frequently in groups with external hexagonal connections (Fig.

3-6). The IH-DD-DLCF group (Fig. 6) presented the lowest gaps

in maladjustment presence. Adding non-cycled groups to comparison,

EH/IH-CON group (Fig. 3) presented the smaller gaps

when compared to the fatigated groups.

Figure 1. Photomicrographs (SEM) of qualitative analysis, Extern Hexagonal connections groups. EH-CON group.

Figure 2. Photomicrographs (SEM) of qualitative analysis, Intern Hexagonal connections groups. IH-CON group.

Table 2. Experimental Groups, mean, standard deviation, coefficient of variance and maintenance torque values expressed in maximum and minimum percentage (%).

Discussion

According to the results of this study, the null hypotheses were

accepted; there were no significant differences among the groups.

The mean value of torque maintenance before the retorque and

mechanical recycling of our samples was described previously

[6]; it was approximately 68%. After complete the experiment,

the mean torque maintenance value was approximately 50%; this

decrease in the removal torque values after retorque and the occlusal

load occurred as expected, regardless of screw type[14] and

these results are following literature [15-17]. The embedment,

with gradual accommodation and adaptation between the contact

interfaces, results in a reduction of the friction coefficient [17].

Besides that, the removal torque values tended to decrease proportionally to the increase in the number of insertion/removal

cycles [16].

It was expected an improvement of torque maintenance in the

experimental coated groups. Dziedzic et al. reported that the carbon

coating on the screw threads reduced the friction in the interface

and improved the preload values [17] and consequently the

clamping force exerted by the abutment on the implant platform.

Due to the low friction coefficient of the DLC, the film should allow

greater preload with the same torque, improving the stability

of the joint [18]. Colpak & Gumus coated abutment screws with

DLC (Oerlikon Balzers) through the plasma vapor deposition

method and reported higher reverse torque values in DLC coated

abutment screws [19].

Additionally, diamond doped DLC films have unique properties

when compared to pure nanocrystalline diamond films or

metal-doped DLC films, which may provide advantages for electrochemical,

optical-window, field emission, or tribological applications

[11]. However, in this research, both coatings presented

similar torque maintenance when compared to uncoated groups.

Contradictory results may be explained by mechanical properties

determined by the method of deposition. Herein we used

PECVD. Each method has its advantages as well as disadvantages

such as high levels of internal stress, poor adhesive properties, or

high sensitivity to ambient conditions [20].

The literature demonstrates that external hexagonal connections

generate higher stress along with the implant, promoting greater

deformations than the internal hexagonal connection, thus IH

has a more favorable biomechanical situation for the prosthetic

performance [21], however, considering the limitations of the

present study, none difference was demonstrated between EH

and IH connections groups. Contradictorily, EH connections

groups demonstrated significant differences while the torque

maintenance values were more stable in the IH groups [6]; there

were no significant differences among IH groups in Lepesqueur’s

study [6]. The authors reported high torque maintenance value in

uncoated screws with external hexagonal connections when compared

to groups coated with diamond-like carbon and coated with

diamond-like carbon doped with diamond nanoparticles [6].

The fatigue simulation of retorqued screws resulted in the increase

of screw surface irregularities, and consequently increased

the coefficient of friction, but decreased the preload of the tightened

joint [22]. There was no screw fracture or loosening of prosthesis

in the presented study, so the stability of the tightened joint

was kept after retorque, which is following literature [23].

Most uncoated screw damages confirm that the DLC film favors

the wearing resistance and protect the coated surface and implant

threads. Coating removal was higher in the DLC nanofilm group

than the DD-DLC group, probably due to the greater roughness

of DLC, even though DLC presented a higher critical load for

delamination [6]. The elevated superficial roughness favors the

coefficient of friction increase, which favors the DLC film removal

during the torque of the screws and retorque procedures.

The granulation of DD-DLC coating over the screws is a characteristic

of this type of coating. The granules were more frequent

in the apical portion of the screw since the deposition process

occurred with the specimen upside-down on a sample-holder; so

this region was favored by the deposition process. The difference

in the number of damages and titanium exposure caused by the

coating removal of screws of different connections was attributed

to the fact that the external hexagonal connection generates high

stress along with the implant, promoting larger deformations than

the internal hexagonal connections [21]. Besides that, the smaller

micro-space found in the internal connection when compared to

the external connection resulted in intimal relation between the

implant and screw surfaces, favoring screwed joint clamping and

promoting coating removal.

Our marginal adaptation findings corroborate with the literature

[23]. The gaps between EH implant-pillar were larger than the

ones observed between IH’s, regardless of screw treatment. The

groups with non-fatigued screws presented smaller gap values,

consequently, their threads promoted better clamping between

the screw and the implant.

A limitation of the study was the lack of rotational misfit measurement.

Additional studies with the use of retorquing in accelerated

life tests, the use of ceramic pillars, and retorqued screws

fracture resistance evaluation should be carried out.

Conclusion

Based on these results, the surface of studied materials (coated/

uncoated) and the type of platform (IH/EH) do not interfere in

the torque maintenance when a retorque is applied.

Acknowledgements & Declarations

RCC thanks the scholarship from Coordination for the Improvement

of Higher Education (CAPES - Coordenação de

Aperfeiçoamento de Pessoal de Nível Superior – Brasil) – Finance

Code 001, in São José dos Campos, Brazil. Authors thanks

Conexão Sistemas de Prótese® (Campinas, SP, Brazil) that provided

the implants to the research.

Ethics approval and consent to participate

Not applicable

Consent for publication

Not applicable

Availability of data and material

Datasets are available from the corresponding author on reasonable

request. The raw data and all related documents supporting

the conclusions of this manuscript will be made available by the

authors, without undue reservation, to any qualified researcher.

Funding

This work was partly supported by the Coordination for the

Improvement of Higher Education (CAPES - Coordenação de

Aperfeiçoamento de Pessoal de Nível Superior – Brasil) – Finance

Code 001, in São José dos Campos, Brazil.

References

-

[1]. Srinivasan M, Meyer S, Mombelli A, Müller F. Dental implants in the

elderly population: a systematic review and meta-analysis. Clin Oral Implants

Res. 2017 Aug;28(8):920-930. Epub 2016 Jun 7. PubMed PMID:

27273468.

[2]. Araújo PM, Filho GS, Ferreira CF, Magalhães Benfatti CA, Cagna DR, Bianchini MA. Mechanical Complications Related to the Retention Screws of Prefabricated Metal Abutments With Different Angulations: A Retrospective Study With 916 Implants. Implant Dent. 2018 Apr;27(2):209-212. PubMed PMID: 29489548.

[3]. de Moraes SL, Verri FR, Santiago JF Jr, Almeida DA, de Mello CC, Pellizzer EP. A 3-D finite element study of the influence of crown-implant ratio on stress distribution. Braz Dent J. 2013 Nov-Dec;24(6):635-41. PubMed PMID: 24474362.

[4]. Mombelli A, Hashim D, Cionca N. What is the impact of titanium particles and biocorrosion on implant survival and complications? A critical review. Clin Oral Implants Res. 2018 Oct;29 Suppl 18:37-53. PubMed PMID: 30306693.

[5]. Callan DP. Dental implant design and oral and systemic health. Compend Contin Educ Dent. 2007 Sep;28(9):482-4, 486-90, 492. PMID: 17907371. [6]. Lepesqueur LS, de Figueiredo VM, Ferreira LL, Sobrinho AS, Massi M, Bottino MA, Nogueira Junior L. Coating dental implant abutment screws with diamondlike carbon doped with diamond nanoparticles: the effect on maintaining torque after mechanical cycling. Int J Oral Maxillofac Implants. 2015 Nov-Dec;30(6):1310-6. PubMed PMID: 26574857.

[7]. Kim SK, Lee JB, Koak JY, Heo SJ, Lee KR, Cho LR, Lee SS. An abutment screw loosening study of a Diamond Like Carbon-coated CP titanium implant. J Oral Rehabil. 2005 May;32(5):346-50. PubMed PMID: 15842243.

[8]. Wu L, Holloway BC, Beesabathina DP, Kalil C, Manos DM. Analysis of diamond-like carbon and Ti/MoS2 coatings on Ti–6Al–4V substrates for applicability to turbine engine applications. Surface and Coatings Technology. 2000 Aug 21;130(2-3):207-17.

[9]. Hauert R, Thorwarth K, Thorwarth G. An overview on diamond-like carbon coatings in medical applications. Surface and Coatings Technology. 2013 Oct 25;233:119-30.

[10]. Assunção WG, Delben JA, Tabata LF, Barão VA, Gomes EA, Garcia IR Jr. Preload evaluation of different screws in external hexagon joint. Implant Dent. 2012 Feb;21(1):46-50. PubMed PMID: 22228458.

[11]. Lian GD, Dickey EC, Ueno M, Sunkara MK. Ru-doped nanostructured carbon films. Diamond and Related Materials. 2002 Dec 1;11(12):1890-6. [12]. Ivanov MG, Ivanov DM. Nanodiamond nanoparticles as additives to lubricants. InUltrananocrystalline Diamond: Synthesis, Properties and Applications: Second Edition 2012 (pp. 457-492).

[13]. Spazzin AO, Henrique GE, Nóbilo MA, Consani RL, Correr-Sobrinho L, Mesquita MF. Effect of retorque on loosening torque of prosthetic screws under two levels of fit of implant-supported dentures. Braz Dent J. 2010 Jan;21(1):12-7. PubMed PMID: 20464315.

[14]. Farina AP, Spazzin AO, Pantoja JM, Consani RL, Mesquita MF. An in vitro comparison of joint stability of implant-supported fixed prosthetic suprastructures retained with different prosthetic screws and levels of fit under masticatory simulation conditions. Int J Oral Maxillofac Implants. 2012 Jul-Aug;27(4):833-8. PubMed PMID: 22848885.

[15]. Farina AP, Spazzin AO, Consani RL, Mesquita MF. Screw joint stability after the application of retorque in implant-supported dentures under simulated masticatory conditions. J Prosthet Dent. 2014 Jun;111(6):499-504. Epub 2014 Jan 11. PubMed PMID: 24423456.

[16]. Cardoso M, Torres MF, Lourenço EJ, de Moraes Telles D, Rodrigues RC, Ribeiro RF. Torque removal evaluation of prosthetic screws after tightening and loosening cycles: an in vitro study. Clin Oral Implants Res. 2012 Apr;23(4):475-80. Epub 2011 Apr 4. PubMed PMID: 21457352.

[17]. Dziedzic DS, Nhata J, Jamcoski VH, Dziedzic M. Assessment of preload in carbon coated prosthetic screws. RSBO Revista Sul-Brasileira de Odontologia. 2012;9(2):137-42.

[18]. Colpak ED, Gumus HO. Effect of Surface Modifications of Abutment Screws on Reverse Torque Values: An In Vitro Study. Int J Prosthodont. 2020 Jul/Aug;33(4):401-409. PubMed PMID: 32639700.

[19]. Penkov OV, Pukha VE, Starikova SL, Khadem M, Starikov VV, Maleev MV, Kim DE. Highly wear-resistant and biocompatible carbon nanocomposite coatings for dental implants. Biomaterials. 2016 Sep;102:130-6. Epub 2016 Jun 15.PubMed PMID: 27336185.

[20]. Torcato LB, Pellizzer EP, Verri FR, Falcón-Antenucci RM, Santiago Júnior JF, de Faria Almeida DA. Influence of parafunctional loading and prosthetic connection on stress distribution: a 3D finite element analysis. J Prosthet Dent. 2015 Nov;114(5):644-51.Epub 2015 Jul 14. PubMed PMID: 26187105.

[21]. Bulaqi HA, Mousavi Mashhadi M, Safari H, Samandari MM, Geramipanah F. Dynamic nature of abutment screw retightening: finite element study of the effect of retightening on the settling effect. J Prosthet Dent. 2015 May;113(5):412-9. Epub 2015 Mar 4. PubMed PMID: 25749092.

[22]. Montero J, Manzano G, Beltrán D, Lynch CD, Suárez-García MJ, Castillo- Oyagüe R. Clinical evaluation of the incidence of prosthetic complications in implant crowns constructed with UCLA castable abutments. A cohort follow-up study. J Dent. 2012 Dec;40(12):1081-9. Epub 2012 Sep 12. Pub- Med PMID: 22982530.

[23]. Diez JS, Brigagão VC, Cunha L, Neves AC, da Silva-Concilio LR. Influence of diamondlike carbon-coated screws on the implant-abutment interface. Int J Oral Maxillofac Implants. 2012 Sep-Oct;27(5):1055-60. PubMed PMID: 23057017.