Effect of Surfosept and Deconex® 53 Disinfectant Agents On The Accuracy And Dimensional Stability Of Panasil Dental Impression Materials: An In-Vitro Experimental Study

Parviz Amini1, Mostafa Alam2, Arash Ghaffarpasand3, Nasim Khaje Dalooei4, Alireza Hadi5, Kamyar Abbasi6*

1 Associate Professor, Department of Prosthodontics, School of Dentistry, Kerman University of Medical Sciences, Kerman, Iran.

2 Assistant Professor, Department of Oral & Maxillofacial Surgery, School of Dentistry, Shahid Beheshti University of Medical Sciences, Tehran, Iran.

3 Postgraduate Resident, Department of Oral & Maxillofacial Surgery, School of Dentistry, Shahid Beheshti University of Medical Sciences, Tehran, Iran.

4 Dentist, Private Practice, Tehran, Iran.

5 Assistant Professor, Department of Prosthodontics, School of Dentistry, Shahid Beheshti University of Medical Sciences, Tehran, Iran.

6 Assistant Professor, Department of Prosthodontics, School of Dentistry, Shahid Beheshti University of Medical Sciences, Tehran, Iran.

*Corresponding Author

Kamyar Abbasi,

Assistant Professor, Department of Prosthodontics, School of Dentistry, Shahid Beheshti University of Medical Sciences, Tehran, Iran.

Tel: 00218927980791

E-mail: kamyar.abb@gmail.com

Received: June 22, 2021; Accepted: November 07, 2021; Published: November 10, 2021

Citation: Parviz Amini, Mostafa Alam, Arash Ghaffarpasand, Nasim Khaje Dalooei, Alireza Hadi, Kamyar Abbasi. Effect of Surfosept and Deconex® 53 Disinfectant Agents On The Accuracy And Dimensional Stability Of Panasil Dental Impression Materials: An In-Vitro Experimental Study. Int J Dentistry Oral Sci. 2021;8(11):4943-4948. doi: dx.doi.org/10.19070/2377-8075-21000999

Copyright: Kamyar Abbasi©2021. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

Abstract

Aim and Objective: Impression materials and BegoStone casts are the main sources of cross-contamination and transmission

of dental infections between dental professionals.Considering the influence of disinfection substanceson the dimensions

of impression materials, this study was aimed to compare the effect of Surfosept and Deconex® 53 on the accuracy and

dimensional stability of dental addition siliconematerial i.e., Panasil®.

Material and Method: This in-vitro study was performed on 30 casts. The samples were divided into one control group and

two experimental groups to be disinfected with Surfosept(1%) and Deconex®53 (2%)using a sequential sampling method

(10 per group).The impressions in the experimental groups (i.e., Surfosept and Deconex®53)were rinsedand dried,thenthe

disinfectant was sprayed on the impressions and remained for 30seconds before pouring with stone. In the control group, the

impressions were onlyrinsedand dried, andwere pouredin 10 minutes. Cast dimensions were measured by a profile projector

device, and the mean values obtained from the experimental groups were compared with those of the control group.

Results: There were no significant differences among the groups regarding the height of the resulting dies without undercut

(P=0.62). Moreover, there was no significant difference among the groups regarding the distance between the two dies

(P=0.77). However, in terms of the diameter of the dies without undercut, a significant difference was observed among the

groups(P<0.005).

Conclusion: In general, no significant difference was encountered between dimensional stability and accuracy of the dental

impressions using Surfosept and Deconex®53 in this study.

2.Introduction

3.Materials and Methods

3.Results

4.Discussion

5.Conclusion

5.References

Abbreviations

Dental Disinfectants; Dental Impression Materials; Silicones.

Introduction

Dental materialsare exposed to various pathogenic microorganismswhich

are potentially harmful [1]. The main sources of

cross-contamination of dental infections include the impression

trays, dental impression materials and BegoStonecasts [2]. Chemical

disinfection has remained a common practical approach to

eliminate micro organisms, since heat or steam sterilization of

impressions and occlusal records cannot be performed due to the

risk of distortion [3]. However, as all disinfectant solutions can

have remarkable effects on the dimensional changes of impression

materials, immersion duration is recommended to be short,

i.e.less than 30 minutes [4].

There is invaluable evidence to support the transmission of microorganisms

through impression materials [5-9]. According to

the literature, most of the materials used in dental laboratories

containvarious infectious microorganisms, such as streptococci

[10, 11]. Egusa et al. estimated the prevalence of Streptococci, Staphylococcus aureus, Methicillin-resistant Staphylococcus, and

Candidain the impressions taken from the patients' mouthsat

100%, 55.6%, 25%,and 9%, respectively, [12]. Therefore, disinfection

of dental impressions can remarkably reduce the number

of bacteria and other microorganisms; however, there is no standard

method or protocolfor proper disinfection ofthe impression

materials [13].

It is of utmost importance to select the suitable material for

disinfectionand to identify the potential problems with each approach

[14-18]. Shelf life, solidification, ease of application, low

price, robustness, and resistance to different kinds of stress are

among suitable characteristics of impression materials [10, 19-

24]. On the other hand, dimensional changes of the impression

materials,following the use ofdisinfectants, are among the main

problems in the process of preparation of dental prostheses,

which could lead to treatment failure.

Silicones are the most common impression materials used to fabricate fixed

dental prosthesis [25]. Recently, the use of addition silicone impressions

is escalateddue to its high accuracy [3]. Addition-

type silicone impression materials with enhanced hydrophilic

properties have the potential to show larger dimensional changes

after disinfection, compared to conventional condensation-type

materials [26]; however, there is a dearth of research in this regard

in the literature.

Deconex® 53 is one of thematerials which iscommonly used

fordisinfecting dentalinstruments. It can be employed to eliminate

a wide range of microorganisms, including tuberculosis and viral

envelope [10]. Surfosept (Reza Rad Co, Iran)is another alcoholbaseddisinfectant

material which is used for cleaning surfaces and

objects. This substance is standardized by the European Medicines

Agency (Standards EN 1040).

The effect of Deconex on the dimensional changes of impression

materials has been investigated in some studies;however,

there is no study assessing the dimensional changes in the casts

disinfected by Surfosept material.Asdisinfecting dental impressionsis

necessary, there is a need to investigate different disinfection

materials and their effects on the characteristics ofimpression

materials,especiallytheir dimensional changes. Therefore, this

study was aimed to determine the effect of two substances (i.e.,

Surfosept and Deconex® 53) on the accuracy and dimensional

stability of dental impressionsmade of addition silicones (i.e., Panasil

®).

Materials And Methods

This in-vitro experimental study was performed on 30 casts. Samples

were divided into one control group and two experimental

groups to be disinfected by Surfosept and Deconex® 53 using a

sequential sampling method (10 per group).

Impressions

The study included two upper and lowersections simulated based

on anintraoral dentate situation (Figure 1). The lowersection had

a metal base including two stainless steel dies with three degrees

taper per each wall. One of the dieswas trimmed in a horizontal

directionat the cervical region (2 mm)to create an undercutwithdepthof

1.5mm and 45 degrees angle. The metal basehad four

guide bars to placing the upper section in an specified direction.

The die base consisted of a metal plate with dimensions of 30mm

width, 60mm height, and 15mm length. The upper section, which

acted as a custom impression tray, was made of metal base with

holesto provide retention for the impression material, andto reduce

inter-section pressure. Additionally, it had 4 holes on 4 sides

to holdthe base bars. This section had the same dimensions as the

lower section but differed in height (12mm). The die base and the

upper and lower sections were made of E.C.N, and the bars and

bushes were made of B.O.Z.

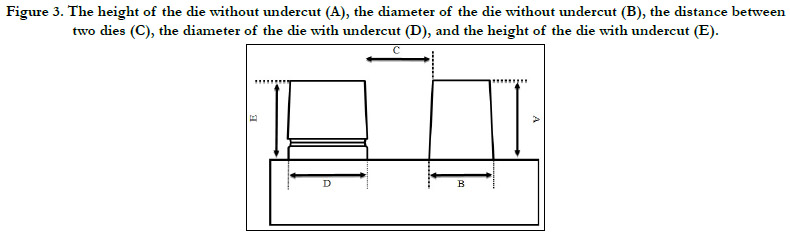

Impression process and preparation of Bego Stone Samples

In this study, two units of putty were mixed with two units ofaccelerator.

The mixture was placed in a tray and the impression was

taken. Initially, the required space for the wash layer was provided

with a 1.5 mm metal spacer. The initial setting time, working time,

and total setting time lasted 120, 120, and 240 seconds, respectively,

at 32° C.

After the solidification of the impression material, the upper and

lower sections were separated and the spacer was removed from

the putty material. Panasil®(Kettenbach Co, Germany) was injected

onthe putty material and around the die, and the impression

was taken again. After hardening, the material was separated

from the tray following the manufacturer's recommendations.

The initial setting time, working time, and thefinal setting time for

the light-bodymaterial were150, 60-90, and 240sec, respectively.

The impressions were left in the room temperature for 30 min,for

the rebound phenomenonto happen. In the next stage, the impression

was pouredusing BegoStone type IV (Wilhelm Herbst

Bremen; Germany). According to the guidelines50 gramof BegoStone

was mixed with 10cc water at 23 °Cfor 30sec, andit was

poured into the impressionin three minutes utilizingslow vibration.

The cast was separatedfrom the impression after one hour

(Figure 2).

Impression and Disinfectant Materials

Soft and lightPanasil® Putty, which areaddition-type silicone impression

materialswere employed in this study. Deconex® 53 is

adisinfectant solution, which is commonly used in hospital settings

for disinfecting flexible and rigid endoscopes. It can also be

utilized to disinfect dental instruments. The recommended concentration

of this substance is 1-2% depending on the expected

effect, while a maximum of 4% concentration is used in certain

circumstances. This solution is composed of Alkyl propylene diamine

guanidinium diacetate, and N-didecylN-methyl-poly (oxyethyl)

ammonium propionate. In this study, Deconex® 53 (1%)

was sprayed on the impressions for 30 sec.

Surfosept is analcohol-based disinfectant which can be used for

eliminating bacteria and viruses, such asinfluenza A virus subtype

H1N1, hepatitis C virus, hepatitis B virus, and human immunodeficiency

virus. This solution contains isopropanol, Didecyldimethylammonium

chloride, ethanol, and other additives.

In the experimental groups (i.e., Surfosept and Deconex® 53), the

impression materials were rinsed and dried after taking impressions.

Subsequently, the disinfectant was sprayed on the impres sions and remained for 30sec before pouring them with stone. In

the control group, the impressions were washed and dried, and

the dental impressions were poured with stone after 30sec.

A profile projector

A profile projector (Tesa Co, Switzerland) with 0.001mm resolution

was utilized to compare the dimensions and geometry of

the samples. The profile projector, which is known as an optical

comparator, is a shadow graph device which uses principles of

optics for accurate measurement and dimentional inspection of

manufactured samples.

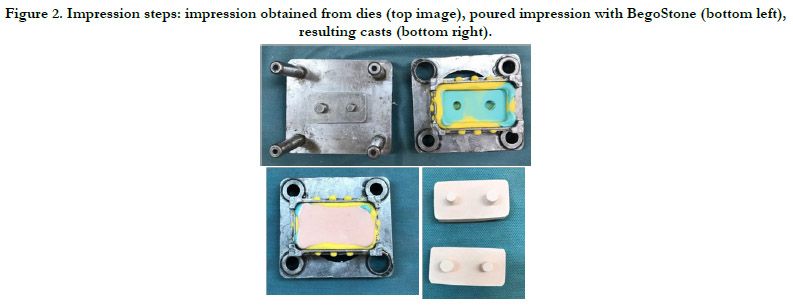

Dimensional measurements

5 variables were specified and examined on cast models. These

factors which were measured by the profile projector include: the

height ofthe die without undercut (A), the diameter of the die

without undercut (B), the distance between two dies (C), the diameter

of the die with undercut (D), and the height of the die

with undercut (E) (Figure 3).

Statistical analysis

The data were analyzed in the IBM SPSS software (version 21).

The three groups were compared in terms of the mean of studied

variables. One-way ANOVAwas used to compare the groups, and

in case of a significant difference, the post hoc test (Tukey test)

was used to determine the differences among groups. A P-value

less than 0.05 was considered statistically significant.

Results

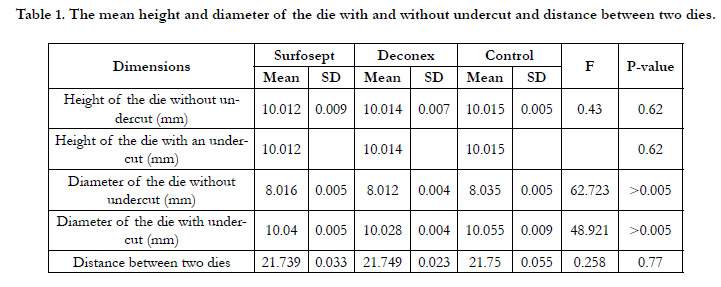

The mean height and diameter of the dies with and without undercut

and distance between two diesare illustrated in Table 1.

There were no significant differences among the control and two

experimental groups in terms of the height of the dieswithout

undercut (P=0.62). Comparison of the groups regarding the

diameter of the dies without undercut showed a significant difference

among them;as a result, the experimental groups had a

lower diameter of the dies without undercut (P<0.005). No significant

difference was observed among the groups in terms of

the distance between two dies (P=0.77). In addition, regardingthe

height of the dieswith undercut, the results revealed no significant difference (P=0.62). However, there was a significant difference

among the groups regarding the diameter of the dies with undercut

(P<0.005).

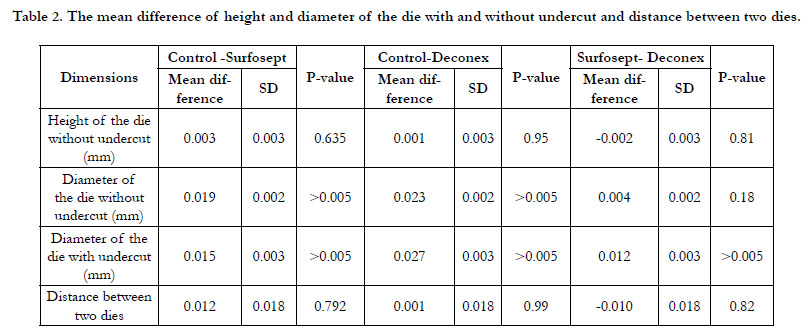

To summarize, there were significant differences between control

and two experimental groups considering the diameter of the

dieswith and without undercut. Nonetheless, no difference was

observed among the groups regarding the height of the dies with

and without undercut, and the distance between the two dies.Table

2 summarizes the results obtained from the Post hoc test.

The results obtained from this study indicated that the height of

the dies with and without undercut and the distance between two

dies had higher accuracy and dimensional stability following the

use of the disinfecting material, compared to the diameter of the

dies with and without undercut.

Figure 2. Impression steps: impression obtained from dies (top image), poured impression with BegoStone (bottom left), resulting casts (bottom right).

Figure 3. The height of the die without undercut (A), the diameter of the die without undercut (B), the distance between two dies (C), the diameter of the die with undercut (D), and the height of the die with undercut (E).

Table 1. The mean height and diameter of the die with and without undercut and distance between two dies.

Table 2. The mean difference of height and diameter of the die with and without undercut and distance between two dies.

Discussion

This study was aimed to determine the effect of two disinfectant

materials (i.e., Surfosept and Deconex® 53) on the accuracy and

dimensional changes of impression materials and the resulting

casts. The dimensional stability of the impression materials can

be influenced by several factors, including the contraction during

the polymerization, and expansion after immersion in disinfectant

solutions [27]. The thermal contraction of addition-type silicone

rubber impression materials may lead to a 10-12µm dimensional

change in cylindrical stone casts for every 1 mm increase in impression

thickness [28].

Addition silicones (i.e., Panasil®) are the impression materials

made of polyvinyl siloxane or vinyl polysiloxane. They have maximum

dimensional stability and minimum dimensional changes

when exposed to disinfectant materials [29]. The polymerization

reaction of these materials helps obtain optimal dimensional stability

[30]. Low viscosity, high hydrophilicity, excellent fluidity

with high thixotropy, and good moisture resistance are the main

characteristics of this substance leading to the increasing use of

it in recent years. Based on the obtained results, both Surfosept

and Deconex® 53 can be used without significant concern,onthe

impression materials made of Panasil®.

Hiraguchi et al. used Addition-type siliconesto assessthe dimensional

changesof impression materials after immersing in glutaraldehyde

(2%) and ortho-phthalaldehyde (0.55%)for 30 min. According

to the results of the aforementioned study, no remarkable

dimensional changes were observed in casts [28]. This findingwas

in line with the results obtained from other similar studies [31] in

which the use of addition silicone (i.e., Panasil®) was suggestedasa

suitableimpression material.

In contrast to the condensation silicones, addition silicones are

based on addition polymerization between divinylpolysiloxane

and polymethylhydrosiloxane with a platinum salt as catalyst.Addition-type silicone rubber impression materials with enhanced

hydrophilic properties contain larger quantities of surfactant,

compared to conventional materials [32]. Some evidence indicates

no change in the wettability of hydrophilic addition-type silicone

rubber impression materials after 18 hour immersion in glutaraldehyde

solution (2%); however, it is possible that the surfactant

in the impression materials leaches out rendering the impressions

less hydrophilic due to long-term immersion in disinfectant solutions.

One the other hand, the dimensions of impression may

change because of imbibition [28]. Due to the novelty of the

addition-type silicone, the type of disinfectant suitable for these

materials is not specified. Therefore, the dimensional accuracy of

the casts should be investigated in more detail.

The results obtained from this study showed no significant difference

between the experimental groups (i.e., Surfosept and

Deconex® 53) regarding the dimensional changes, except for the

diameter of the dies with and without undercut. It seems that

Deconex® 53 tends to be able to absorb water out of the air,

which is consistent to the hydrophilic property of an addition

silicone material. However, the use of Deconex® 53 with alginate

and polyether should be performed with cautionsince eliminating

microorganisms in these material could be compromised [10].

Hamedi rad et al. evaluated the dimensional stability of alginate

impressions following disinfection. The samples were divided

into four groupsto be disinfected with Sodium Hypochlorite,

Micro 10, Glutaraldehyde, and Deconex. They sprayed Micro 10

disinfectant, whereas other disinfectants were applied using immersion

technique [33]. In this study, the Deconexdis infectant

led to the maximum level of dimensional changes, which does

not comply with the findings of our study. This difference may

be due to the utilization of adifferent method for disinfection, i.e.

immersion technique, in contrast to the present study where the

spraying method was used.

In another study conducted by Ghasemi et al., Deconex, Sodium

hypochlorite (25.5%), and Epimax were utilized to disinfect impression

materials [10]. According to the results, no significant

difference was observed among the impressionsin terms of the

dimensional changes after disinfection. This finding is consistent

with the results obtained from the current study. It seems that

the use of Deconex with the spraying method hasmore benefits,

compared to the immersiontechnique. Additionally, the effect of

immersion of polyvinylsiloxane moldsin sodium hypochlorite

(5.25%) led to dimensional changes, such as shrinkage in impression

material [34].

Similarly, a study was conducted by Sabouri et al. on 30 impressions

to determine the effect of disinfectants on dimensional

changes of impression materials. In this study, 20 impressions

were disinfected by sodium hypochlorite and acid glutaraldehyde

(10 impressions per group) and 10 impressions were considered

as a control group. They rinsed impressions with cold water and

stored them at room temperature for 30 and 20 min in the disinfected

and control groups, respectively. Similar to our study, the

height and diameters of the dies and the distance between the

dies were measured in three groups. They showed no significant

differencesbetween the disinfected and control groups regarding

the dimensional changes [35].

Based on the American Dental Association guideline, the immersion

of impression materials in disinfectant solutions should not

be longer than 30 min [12]. In our study, the disinfectant solutions

were sprayed on impressions for 30 seconds. Carvalhal et

al. performed a study to determine the effects of disinfectant solutions

on the dimensional changes of the impression materials.

Four elastomeric impression materials (i.e., Xantopren, Express,

Permlastic, and Soft Impregum) were used to compare the effect

of immersion time on the dimensional changes of casts made

with each of these material. Dimensional changes were reported

in all materials over time, except for immersion periods lower

than 20 min [36]. In another study, Sodium hypochlorite (25.5%),

Deconex, and Sanosil were employed for disinfecting impressionsfor8-

10 min periods, and the results were acceptable in terms

of accuracy and dimensional stability of the material [10].

Conclusions

Based on the obtained results, no difference was reported between

the experimental and control groups regarding the height of the

dies without undercut. In addition, no difference was reported

between the two experimental groups and the control group in

terms of the distance between two dies. However, a difference

was observed between the experimental and control groups in

terms of the diameter of the dies both with and without undercut.

In general, no significant difference was observed between

Surfosept (1%) and Deconex® 53 (2%) in terms of influencing

the dimensions or accuracy of the impression materials.

Acknowledgments

The authors would like to thank the authoritiesat Kerman Dental

School, Kerman University of Medical Sciences, Kerman, Iran,

for their cooperation inconducting this study.

References

-

[1]. Aroori S, Spence RA. Carpal tunnel syndrome. Ulster Med J. 2008

Jan;77(1):6-17. PubMed PMID: 18269111.

[2]. Haghighat A, Khosrawi S, Kelishadi A, Sajadieh S, Badrian H. Prevalence of clinical findings of carpal tunnel syndrome in Isfahanian dentists. Adv Biomed Res. 2012;1:13. PubMed PMID: 23210072.

[3]. Bland JD. Carpal tunnel syndrome. BMJ. 2007 Aug 18;335(7615):343-6. PubMed PMID: 17703044.

[4]. Alhusain FA, Almohrij M, Althukeir F, Alshater A, Alghamdi B, Masuadi E, Basudan A. Prevalence of carpal tunnel syndrome symptoms among dentists working in Riyadh. Ann Saudi Med. 2019 Mar-Apr;39(2):104-111. Pub- Med PMID: 30905925.

[5]. Khosrawi S, Maghrouri R. The prevalence and severity of carpal tunnel syndrome during pregnancy. Adv Biomed Res. 2012;1:43. PubMed PMID: 23326774.

[6]. Oktayoglu P, Nas K, Kilinç F, Tasdemir N, Bozkurt M, Yildiz I. Assessment of the Presence of Carpal Tunnel Syndrome in Patients with Diabetes Mellitus, Hypothyroidism and Acromegaly. J ClinDiagn Res. 2015 Jun;9(6):OC14-8. PubMed PMID: 26266148.

[7]. Ahmed A, Khan A, Siddiqui Z, AHMED MR, Askari H, Zahid A. Prevalence of carpel tunnel syndrome in the dentists working in Karachi. Pakistan Oral & Dental Journal. 2014 Dec 1;34(4).

[8]. Chin DH, Jones NF. Repetitive motion hand disorders. J Calif Dent Assoc. 2002 Feb;30(2):149-60. PubMed PMID: 11883427.

[9]. Brown PN. What's ailing us? Prevalence and type of long-term disabilities among an insured cohort of orthodontists. Am J OrthodDentofacialOrthop. 2004 Jan;125(1):3-7. PubMed PMID: 14718873.

[10]. BorhanHaghighi A, Khosropanah H, Vahidnia F, Esmailzadeh S, Emami Z. Association of dental practice as a risk factor in the development of carpal tunnel syndrome. J Dent (Shiraz). 2013 Mar;14(1):37-40. PubMed PMID: 24724115.

[11]. Inbasekaran D, Sankari M, Nambi SG. Prevalence of carpal tunnel syndrome among dentists in Chennai, India. Drug Invention Today. 2018 Nov 2;10(3):3262-5.

[12]. Lalumandier JA, McPhee SD. Prevalence and risk factors of hand problems and carpal tunnel syndrome among dental hygienists. J Dent Hyg. PubMed PMID: 11475758.

[13]. Leggat PA, Kedjarune U, Smith DR. Occupational health problems in modern dentistry: a review. Ind Health. 2007 Oct;45(5):611-21. PubMed PMID: 18057804.

[14]. Munirah MA, Normastura AR, Azizah Y, Aziah D. Prevalence of probable carpal tunnel syndrome and its associated factors among dentists in Kelantan. International Journal of Collaborative Research on Internal Medicine & Public Health. 2014;6(8).

[15]. Ehsan M, Ehsan S, Arshad H. Frequency of carpal tunnel syndrome in dentists working in government hospitals of lahore. Int J Sci Res. 2013;14:2319- 7064.

[16]. SayeghGhoussoub M, Ghoussoub K, Moucharrafieh L, Khoury A, Sleilaty G, Rifaï K. Troubles musculo-squelettiques chez une population de chirurgiens- dentisteslibanais: Fréquence et facteurs de risque [Musculo-skeletal problems among Lebanese dental surgeons. Occurrence and risk factors]. J Med Liban. 2005 Jan-Mar;53(1):21-7. PubMed PMID: 16398209.

[17]. oic L, Bojnec V, Lonzaric D, JesenekPape B. An advanced stage of carpal tunnel syndrome - is night-time splinting still effective? Int J Occup Med Environ Health. 2020 Oct 20;33(6):771-780. PubMed PMID: 32929289.