Surface Roughness And Colour Stability Of Dental Porcelain Treated With Different Polishing Methods

Ismail NH, Awang RA*, Kung Ho S

School of Dental Sciences, Health Campus, Universiti Sains Malaysia, 16150 Kubang Kerian, Kelantan, Malaysia.

*Corresponding Author

Awang RA,

School of Dental Sciences, Health Campus, Universiti Sains Malaysia, 16150 Kubang Kerian, Kelantan, Malaysia.

E-mail: rjazman@usm.my

Received: April 23, 2020; Accepted: June 29, 2020; Published: July 02, 2020

Citation:Ismail NH, Awang RA, Kung Ho S. Surface Roughness And Colour Stability Of Dental Porcelain Treated With Different Polishing Methods. Int J Dentistry Oral Sci. 2020;7(6):766-769. doi: dx.doi.org/10.19070/2377-8075-20000150

Copyright: Awang RA©2020. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

Abstract

Background: The study aims to investigate the effect of different polishing methods on the dental porcelain surface roughness

and tea extract staining resistance.

Methods: A total of 40 disc-shaped dental porcelain of 10mm diameter and 2mm thickness were divided into four groups:

Group A (Glaze), untreated control; Group B (Polishing paste), using slow speed green stone bur and followed by diamond

polishing paste; Group C (NTI), using NTI CeraGlaze polishing kits; and Group D (Identoflex), using Identoflex Diamond

Ceramic Polisher. The specimens were then subjected to a baseline measurement for surface roughness and colour shade using

a surface profilometer and digital spectrophotometer, respectively. The glaze layer was removed using a medium-grit diamond

rotary bur, followed by 60 seconds polishing according to the assigned method. A second surface roughness measurement

ensued. The specimens were then subjected to thermal cycling between 5°C and 55°C for 2000 cycles, followed by 30 days

staining in a tea extract solution. A second colour shade measurement ensued.

Results: The surface roughness of dental porcelain was highest in the Polishing paste group (p < 0.05), and the NTI and Identoflex group were not significantly different from the Glaze group (p > 0.05). In all test groups, the Glaze group shows

superiority in colour stability with DE value significantly higher compared to all test group (p < 0.05).

Conclusion: Although the mechanical polishing can restore the smoothness of the glazed surface, it cannot restore the ability

to resist tea extract staining.

2.Materials and Methods

3.Surface Roughness Measurement

4.Colour Shade Measurement

5.Statistical Analysis

6.Result

7.Discussion

8.Acknowledgement

9.References

Introduction

stability in the oral environment. They have been used as a restoration

material in restoring carious and missing teeth, such as in

crowns, veneers, inlays, onlays, denture teeth, and bridges [1, 2].

Dental porcelains possess a superior strength compared to other

restorations such as amalgam, composite restoration and resinmodified

glass ionomer cement [3-5], and the porcelain glazed

gives a natural appearance of a restored tooth, reducing the wear

of opposing teeth, as well as facilitate good oral hygiene [6-8].

However, in a situation like a high bite, crack, chipping, over

contour or overhanging margin, a chairside adjustment has to be

carried out on porcelain glaze before cementation of the restoration.

In the past, chairside porcelain surface adjustment has been

associated with increase abrasive wear and plaque accumulation

[9, 10]. If a chairside adjustment has to be done, it should be followed

by a re-glazing procedure to get the optimum advantage of

the porcelain restoration. Nevertheless, not all dental clinic setting

has porcelain glazing facilities, and to get it done in the laboratory

will inevitably delay the treatment procedure. In the advent of

technology in dental porcelain, more efficient porcelain polishing

kits have been developed.

Studies have shown that the chairside porcelain polishing kits either

used alone or in combination can restore the glaze surface

smoothness of adjusted dental porcelain surface [11-14]. On the

contrary, studies also showed contradicting findings, that some

of the porcelain polishing procedures produced inferior smoothness

of dental porcelain compared to the glaze surface [15-17].

Apart from that, studies also showed that a porcelain surface

smoothness superior to porcelain glaze can be achieved using

the porcelain polishing procedures [18, 19]. These contradicting

findings were assumed to arise from the difference in the polishing

method, such as pressure and time applied, types of lubricant

used and speed of the handpiece. There are also other possible

contributing factors such as properties of porcelain, characteristics of abrasive materials, and type of abrasive carrier [20]. Unfortunately,

the inadequate porcelain surface smoothness from the

chairside polishing procedure has also been associated with the

reduced ability of the dental porcelain to withstand staining from

common beverages like tea and coffee [14, 21]. Since the literature

on the effect of chairside porcelain polishing methods were still

limited, and the findings were inconclusive, this study is hoped

to give some contribution in understanding the role of porcelain

polishing methods in chairside procedure. The aim of the study

was to evaluate the effect of dental porcelain polishing methods

on the porcelain surface roughness. At the same time, the study

also assessed the impact of porcelain surface roughness on the

tea extract staining.

Materials and Methods

The lithium disilicate IPS e.max Press glass-ceramic ingots (Ivoclar

Vivadent, UK) were used to prepare the porcelain specimens.

A total of 40 disc-shaped porcelain specimens measuring 10 mm

in diameter and 2 mm in thickness were made by a single investigator.

The lost wax casting technique was used in the porcelain

specimen preparations. For each specimen, a disc-shaped wax pattern

was prepared using a silicone mould. A digital calliper (Mitaka,

Japan) was used to ensure consistency in the wax’s dimensions.

The wax specimens were then invested in a phosphate-bonded

investment material (Interfine K+B Speed, Interdent, Slovenia).

The porcelain ingots were pressed into disc-shaped porcelains using

the lost-wax casting technique. The press furnace, Programat

EP 3000 (Ivoclar Vivodent, UK) was used in the pressing process

following the manufacturer’s instruction. All specimens were allowed

to cool and then finished with a medium-grit diamond bur

to remove any irregularities. The specimens were then sprayed

with Triton SLA steam blaster (BEGO, USA) before placed in a

furnace to obtain an auto glazed surface. Specimens were inspected

under a light microscope (Leica, Germany) to ensure a smooth

surface, and the defective specimen was removed and replaced.

The specimens were then randomly divided into 4 groups of 10

specimens each according to polishing methods: Group A (Glaze),

the specimens were untreated and served as control; Group B

(Polishing paste), the specimens were polished using slow speed

green stone bur (Edenta, Germany) and followed by diamond

polishing paste (Shofu, Japan); Group C (NTI), the specimens

were polished using NTI CeraGlaze polishing kits (Kerr, Switzerland);

and Group D (Identoflex), the specimens were polished

using Identoflex Diamond Ceramic Polisher (Kerr, Switzerland).

The specimens were then subjected to a baseline measurement

for surface roughness and colour shade using surface profilometer

(Tokyo Seimitsu Co. LTD, Japan) and digital spectrophotometer,

VITA Easyshade Advance 4.0 (VITA, Germany) respectively.

Group A (Glaze) served as a control, and no surface treatment

was done. As for the test group, the glaze layer was removed using

a medium-grit diamond rotary bur with a slow speed handpiece

under water spray to simulate clinical repair procedure. The test

group specimens were then subjected to the mechanical polishing

procedure as assigned to each group for 60 seconds. After completing

the surface treatment, the specimens were subjected to a

second surface roughness measurement.

The specimens were then subjected to cyclic thermal stress for

2000 cycles using distilled water between 5°C and 55°C with a dwell time of 30 seconds and a transfer time of 15 seconds. The

procedure was carried out to simulate the service life of dental

porcelain in the oral cavity. The specimens were subjected to

staining for 30 days in a tea extract solution at room temperature.

The tea extract solution was prepared according to the company’s

instruction by adding 5 tea bags (BOH, Malaysia) into 1000 ml of

freshly boiled water and brewed for 2 minutes. Teabags were then

removed, and the tea extract solution was left to cool at room

temperature. This is followed by a second measurement of colour

shade.

Surface Roughness Measurement

The measurement of surface roughness was made using profilometer

(Tokyo Seimitsu Co. LTD, Japan), where Ra was chosen

as the roughness parameter. Ra was calculated as the roughness

average of a surface measured microscopic peaks and valleys that

have been traced by the profilometer [22]. A higher Ra value indicates

a rougher surface. The stylus used in this profilometer has

a tip radius of 2 μm. The profilometer was calibrated before the

measurement of each group. For the measurement process, the

profilometer was set to a cut off value of 0.25 mm for detecting

surface irregularities. A sample measuring distance was 2 mm, and

a constant measuring speed and force were set at 0.06 mm/s and

0.7 N, respectively. During the surface roughness measurement,

the specimen was stabilised with silicone impression material into

a Perspex mould. Three readings were taken for each sample,

where all measurements were carried out as close as possible to

the sample centre. The Ra value for each sample was calculated

from the average of the three measurements.

Colour Shade Measurement

The measurement of colour shade was made using a spectrophotometer,

VITA Easyshade Advance 4.0 (VITA, Germany). Before

colour measurement, the spectrophotometer was calibrated

against the calibration block as directed in the instruction manual.

Colourimetric measurements of the specimens were performed

according to the CIELAB colour scale, recording the L*, a*, and

b* values. For each specimen, three measurements were performed

on a white background to get a mean value for the L*, a*,

and b*. The colour changes (ΔE) was calculated using the following

formula [23], ΔE = [(ΔL)2 + (Δa)2 + (Δb)2]1/2.

Statistical Analysis

Since the data were not normally distributed when analysed using

Shapiro-Wilk test (p < 0.05), comparing more than two variables

was carried out using the Kruskal-Wallis test, which was followed

by pair-wise comparisons using a series of Mann-Whitney U tests.

Significance level was set at p = 0.05.

Result

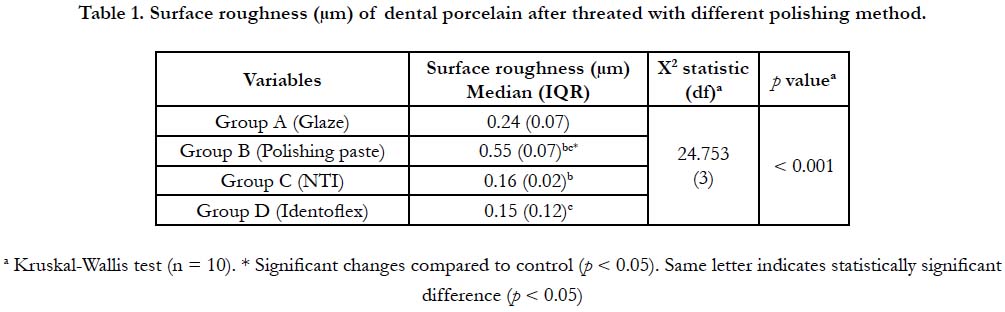

Table 1 shows the surface roughness of dental porcelain after

treated with different polishing methods. The surface roughness

of dental porcelain was significantly higher in the Polishing paste

group when compared to the Glaze group (p < 0.05). However,

in the NTI and Identoflex group, the surface roughnesses were

found not significantly different from the Glaze group (p > 0.05).

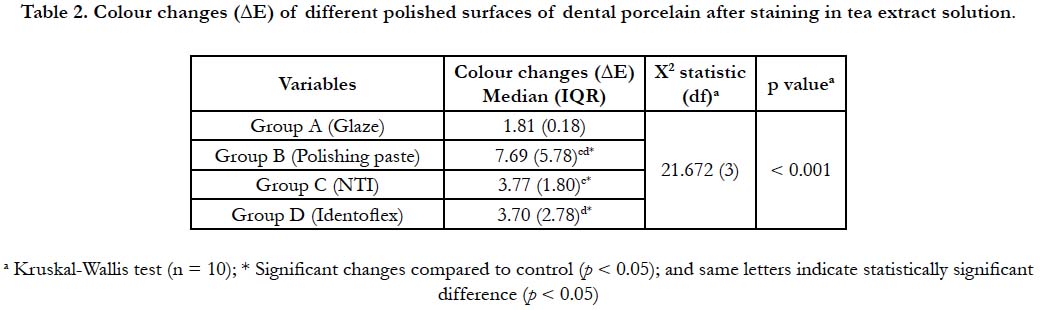

Additionally, Table 2 shows the colour changes (ΔE) of different porcelain polished surface condition after staining in tea extract solution. In all test groups, the Glaze group shows superiority in colour stability. The ΔE value was statistically significantly higher compared to all test groups (p < 0.05). The Polishing paste group was statistically significantly higher in ΔE values compared to NTI and Identoflex group (p < 0.05).

Table 2. Colour changes (ΔE) of different polished surfaces of dental porcelain after staining in tea extract solution.

Discussion

Our study showed that polishing the roughened porcelain surface

using a slow speed green stone bur (Edenta AG, Germany) and

diamond polishing paste (Shofu Inc., Japan) produced a significantly

higher surface roughness compared to the glazed porcelain.

Polishing a roughened porcelain surface using different types

of diamond polishing paste alone has been shown to give higher

surface roughness compared to the glazed porcelain [13, 24]. The

finding appears similar when the diamond particle-impregnated

wax (diamond wax) was used [25]. Seemingly, the diamond paste

or wax possibly only beneficial in reducing the height of the maximum

surface peak and it is not meant for clearing the mass of

roughened surface. It is not clear if the diamond paste or wax on

its own efficient enough in reducing surface roughness (Martinez-

Gomis et al., 2003). It was shown that for the diamond paste or

wax to be effective, the roughened porcelain surface has to be prereduced

sufficiently using either porcelain adjustment kit, polishing

wheel, polishing stick, or Sof-lex discs [13, 25, 26]. Diamond

polishing paste has been shown to produce a smooth porcelain

surface comparable to the glazed porcelain when used in combination

with other porcelain adjustment kits such as polishing

disks [24]. Although a slow speed green stone bur was used in this

study to pre-reduce the porcelain surface roughness, the coarse

finishing of the stone probably too rough to be eliminated by diamond polishing paste.

This study also revealed that the NTI CeraGlaze polishing kits and

Identoflex Diamond Ceramic Polisher kits were able to smoothen

the roughened porcelain surface comparable to the glazed surface.

This is in line with the previous study that showed the capability

of the NTI CeraGlaze polishing kits in smoothing the roughened

porcelain surface to the level similar to glazed porcelain [11, 27].

Also, a profilometer analysis revealed that Identoflex system was

capable of producing porcelain surface roughness equal to the

glazed surface. However, when the analysis was extended to the

microscopic level using the atomic force microscope (AFM), the

Identoflex system was shown incapable of producing the surface

roughness comparable to the glazed porcelain [17].

In this study, the polished porcelain surface produced by different

mechanical polishing procedure was evaluated for their ability to

resist tea extract staining in comparison to the glazed surface. Our

finding showed that the ΔE value of all polishing groups; Polishing

paste, NTI and Identoflex revealed the median ΔE values of

3.70 or higher, which is categorised as clear noticeable colour difference

[28]. On the other hand, the glazed surface presented with

the median ΔE values of less than 2, which is characterised as noticeable

only by an experienced observer. Statistical analysis also

showed that all the polishing groups (Polishing paste, NTI and

Identoflex) presented with significantly higher median ΔE values

when compared to the glaze surface. The Polishing paste group

showed statistically significantly higher median ΔE values when

compared to the NTI and Identoflex groups (p < 0.05).

Different porcelain polishing procedures have been shown to

produce polished porcelain surfaces that have a distinct ability to

withstand staining from common beverages like coffee and tea

[29]. This could be due to the variation in surface roughness created by different polishing techniques. Moreover, porcelain glazed

surface has been shown to have a better ability in resisting tea or

coffee extract staining when compared to mechanically polished

porcelain surface [30-32]. Evaluation using methylene blue staining

also showed better colour stability of the porcelain glazed surface

when compared to various methods of mechanical porcelain

polishing methods (Yilmaz et al., 2008).

Within the limitation of this study, we observed that with a good

selection of porcelain polishing technique and material, a fractured

or roughened porcelain surface can be polished to achieve

the surface roughness of at least equal to the glaze surface when

evaluated using a profilometer. However, it is known that at a

microstructure level, the smoothness of the glazed surface is

superior compared to the mechanically polished surface. This is

probably the best explanation to describe the inferiority of the

mechanically polished porcelain colour stability compared to the

glaze surface. Hence, perhaps, it is better when performing porcelain

adjustment on the aesthetic concern area, the porcelain is

re-glazed before cementation. The main limitation of our study

was we only evaluate one type of dental porcelain. Studies showed

that different types of dental porcelain produced a varying degree

of surface roughness after mechanical chairside polishing, which

also had various ability in resisting beverage staining [11, 14, 21].

This study also can be improved by evaluating the surface roughness

degree at the microscopic level using atomic force microscope

(AFM).

Acknowledgement

This study was supported by the Universiti Sains Malaysia (USM) through the USM research grant, Grant no: 304/PPSG/61313149 and 304/PPSG/61313137.

References

- Ho GW, Matinlinna JP. Insights on ceramics as dental materials. Part I: ceramic material types in dentistry. Silicon. 2011 Jul 1;3(3):109-15.

- Bayne SC, Ferracane JL, Marshall GW, Marshall SJ, van Noort R. The evolution of dental materials over the past century: silver and gold to tooth color and beyond. J Dent Res. 2019 Mar;98(3):257-65.. Pubmed PMID: 30784370.

- Kamble VD, Parkhedkar RD. Esthetic rehabilitation of discolored anterior teeth with porcelain veneers. Contemp Clin Dent. 2013 Jan;4(1):124. Pubmed PMID: 23853471.

- Rashid H. The effect of surface roughness on ceramics used in dentistry: A review of literature. Eur J Dent. 2014 Oct;8(04):571-9. Pubmed PMID: 25512743.

- Pini NP, Aguiar FH, Lima DA, Lovadino JR, Terada RS, Pascotto RC. Advances in dental veneers: materials, applications, and techniques. Clin Cosmet Investig Dent. 2012;4:9-16.Pubmed PMID: 23674920.

- de Andrade OS, Borges GA, Stefani A, Fujiy F, Battistella P. A step-bystep ultraconservative esthetic rehabilitation using lithium disilicate ceramic. Quintessence Dent Technol. 2010 Feb;33:114-31.Pubmed PMID: 28884029.

- Jefferies SR. The art and science of abrasive finishing and polishing in restorative dentistry. Dent Clin North Am. 1998 Oct;42(4):613-27.

- Raimondo Jr RL, Richardson JT, Wiedner B. Polished versus autoglazed dental porcelain. The J Prosthet Dent. 1990 Nov 1;64(5):553-7. Pubmed PMID: 2090814 .

- Monasky GE, Taylor DF. Studies on the wear of porcelain, enamel, and gold. J Prosthet Dent. 1971 Mar 1;25(3):299-306. Pubmed PMID: 5276853.

- Swartz ML, Phillips RW. Comparison of bacterial accumulations on rough and smooth enamel surfaces. J Periodontol. 1957 Oct;28(4):304-7.

- Sarikaya I, Güler AU. Effects of different polishing techniques on the surface roughness of dental porcelains. J Appl Oral Sci. 2010 Feb;18(1):10-6.

- Kim IJ, Lee YK, Lim BS, Kim CW. Effect of surface topography on the color of dental porcelain. J Mater Sci Mater Med. 2003 May 1;14(5):405-9. 14:405–409. Pubmed PMID: 15348443.

- Sarac D, Sarac YS, Yuzbasioglu E, Bal S. The effects of porcelain polishing systems on the color and surface texture of feldspathic porcelain. J Prosthet Dent. 2006 Aug 1;96(2):122-8.

- Pradíes G, Godoy‐Ruiz L, Özcan M, Moreno‐Hay I, Martínez‐Rus F. Analysis of surface roughness, fracture toughness, and weibull characteristics of different framework-veneer dental ceramic assemblies after grinding, polishing, and glazing. J Prosthodont. 2019 Jan;28(1):e216-21.

- Singh A, Sengupta B, Kuckreja H, Kuckreja KB. An in vitro study to compare glazed and polished surfaces of feldspathic porcelain and comparing three different polishing systems. Indian J Dent Sci. 2017 Sep 1;9(5):21–26.

- Steiner R, Beier US, Heiss-Kisielewsky I, Engelmeier R, Dumfahrt H, Dhima M. Adjusting dental ceramics: An in vitro evaluation of the ability of various ceramic polishing kits to mimic glazed dental ceramic surface. J Prosthet Dent. 2015 Jun 1;113(6):616-22.

- Tholt B, Miranda-Júnior WG, Prioli R, Thompson J, Oda M. Surface roughness in ceramics with different finishing techniques using atomic force microscope and profilometer.Oper Dent 31:442–449.Pubmed PMID: 16924984.

- Flury S, Lussi A, Zimmerli B. Performance of different polishing techniques for direct CAD/CAM ceramic restorations. Oper Dent 35:470–481. Pubmed PMID: 20672733.

- Anmol C, Soni S. Effect of two different finishing systems on surface roughness of feldspathic and fluorapatite porcelains in ceramo-metal restorations: Comparative in vitro study.J Int Soc Prev Community Dent 4:22–28. Pubmed PMID: 24818090.

- Jefferies SR. Abrasive finishing and polishing in restorative dentistry: a stateof- the-art review. Dental Clinics of North America. Dent Clin North Am 51:379–97.Pubmed PMID: 17532918.

- Soygun K, Varol O, Ozer A, Bolayir G. Investigations on the effects of mouthrinses on the colour stability and surface roughness of different dental bioceramics. J Adv Prosthodont 9:200–207. Pubmed PMID: 28680552.

- Fuzzi M, Zaccheroni Z, Vallania G. Scanning electron microscopy and profilometer evaluation of glazed and polished dental porcelain. Int J Prosthodont. 1996 Sep 1;9(5).

- Johnston WM. Color measurement in dentistry.J Dent 37 Suppl 1:e2-6. Pubmed PMID: 19406551.

- Kim HK, Kim SH, Lee JB, Ha SR. Effects of surface treatments on the translucency, opalescence, and surface texture of dental monolithic zirconia ceramics.J Prosthet Dent 115:773–779.

- Manjuran NG, Sreelal T. An in vitro study to identify a ceramic polishing protocol effecting smoothness superior to glazed surface. J Indian Prosthodont Soc. 2014 Sep 1;14(3):219-27.

- Martínez-Gomis J, Bizar J, Anglada JM, Samsó J, Peraire M. Comparative evaluation of four finishing systems on one ceramic surface. Int J Prosthodont. 2003 Jan 1;16(1):74–77.Pubmed PMID: 12675460.

- Hmaidouch R, Müller WD, Lauer HC, Weigl P. Surface roughness of zirconia for full-contour crowns after clinically simulated grinding and polishing. Int J Oral Sci. 2014 Dec;6(4):241-6.

- WS Tatol M. M. Colour difference ΔE-A survey. Mach. Graph. Vis. 2011;20:383-411.

- Sarıkaya I, Yerliyurt K, Hayran Y. Effect of surface finishing on the colour stability and translucency of dental ceramics. BMC oral health. 2018 Dec 1;18(1):40. https://scholar.google.com/scholar?hl=en&as_sdt=0%2C5&q= +Effect+of+surface+finishing+on+the+colour+stability+and+translucency+o f+dental++ceramics&btnG=

- Sarikaya I, Güler AU. Effects of different surface treatments on the color stability of various dental porcelains. J Dent Sci. 2011 Jun 1;6(2):65-71.

- Kanat-Ertürk B. Color Stability of CAD/CAM Ceramics Prepared with Different Surface Finishing Procedures. J Prosthodont.2020; 29:166-172.

- Acar O, Yilmaz B, Altintas SH, Chandrasekaran I, Johnston WM. Color stainability of CAD/CAM and nanocomposite resin materials. J Prosthet Dent. 2016 Jan 1;115(1):71-5.