The Effect of Fluoride on Beta-Titanium Orthodontic Wire's Surface Texture and Friction Resistance

Abbassy MA1,2, Bakry AS3,4*

1Assistant professor, Orthodontic Science Department, King Abdulaziz University, Jeddah, Saudi Arabia.

2Alexandria University Hospital, Alexandria, Egypt.

3 Assistant Professor at the Operative Dentistry Department, Faculty of Dentistry, King Abdulaziz University, Jeddah, Saudia Arabia.

4 Associate professor at the Conservative Dentistry Department, Faculty of Dentistry, Alexandria University, Egypt.

*Corresponding Author

Dr. Ahmed Samir Bakry,

Fellow at Japan Society for the Promotion of Science,

Cariology and Operative, Dentistry,

Department of Restorative Sciences, Graduate School,

Tokyo Medical and Dental University, 1-5-45, Yushima, Bunkyo-ku,

Tokyo 113-8549, Japan.

E-mail: drahmedbakry@gmail.com

Article Type: Research Article

Received: January 03, 2015 Accepted: February 12, 2015 Published: February 14, 2015

Citation: Mona A. Abbassy, Ahmed. S. Bakry (2015) The Effect of Fluoride on Beta-Titanium Orthodontic Wires` Surface Texture and Friction Resistance. Int J Dentistry Oral Sci. 2(2) 47-52. doi: dx.doi.org/10.19070/2377-8075-1500011

Copyright: Ahmed. S. Bakry© 2015. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

Abstract

Objectives: The aim of this study is to investigate the effect of fluoride application on the surface properties and frictional

resistance of two types of orthodontic archwires.

Materials and Methods: A total of sixty stainless-steel, and beta-titanium orthodontic archwires in-addition to fifty ceramic brackets were examined in-vitro and in-situ. The friction resistance of all wires with ceramic brackets before/after topical fluoride application were examined in-vitro and in-situ. Moreover, surface properties of the tested wires before/after fluoride application and before/after friction test were examined by scanning electron microscope (SEM). Paired t-test and Dunnett t-test were used to compare frictional resistance of the stainless-steel wires to the beta titanium wires as-received, in-vitro and in-situ (p≤ 0.05).

Results: Beta-titanium wires recorded significant high friction resistance when compared to stainless-steel wires. Fluoride application did not significantly affect the friction resistance of the tested wires. SEM observation revealed the roughness of as-received beta-titanium wires and the deterioration of its surface texture after fluoride application in-vitro and in-situ.

Conclusion: Beta-titanium wires recorded high friction resistance when compared to stainlesssteel wires under the asreceived,

in-vitro and in-situ conditions, moreover, fluoride application did not affect friction resistance of beta-titanium

wires while it affected its surface properties.

2.Materials and Methods

2.1 In-vitro Study

2.2 In-situ Study

2.3 Frictional force Examination

2.4 Scanning Electron Microscope Examination

2.5 Statistical Analysis

3.Results

3.1 Friction Resistance Test

3.2 Scanning Electron Microscope

4.Discussion

5.Conclusion

6.Acknowledgement

7.References

Introduction

The introduction of ceramic brackets and titanium wires used during orthodontic treatment enabled orthodontists to provide their patients with excellent esthetics and controlled tooth movement during their treatment. However, the various agents used for maintaining good oral hygiene during orthodontic treatment may affect the physical properties of titanium wires, and thus may increase the frictional forces between ceramic brackets and titanium

wires. Consequently, this may affect the outcome of orthodontic treatment [1- 4].

Friction is defined as a force that delays or resists the relative motion of two objects in contact, and its direction is tangential to the common interface of the two surfaces [4, 5]. Friction is an important factor in sliding mechanics, where the arch-wire must slide through the bracket slots and tube [5, 6]. High levels of frictional force could result in debonding of the bracket, associated with either a small dental movement or no movement at all. When friction prevents movement of the tooth to which the bracket is attached, friction can reduce the available force by almost 40%, resulting in an anchorage loss [5,7, 8].

Correct selection of orthodontic brackets and wires suitable for each case is the first step for achieving a proper orthodontic movement that can be applied to obtain optimum biologic tissue response [3, 5]. The maintenance of good oral hygiene and caries control is the second step to ensure the success of orthodontic treatment outcome. Fluoride prophylactic agents, such as acidulated phosphate fluorides (APF), have been used extensively for remineralization of white spot lesions around orthodontic brackets. However, the fluoride ions in the prophylactic agents have been reported to cause corrosion and discoloration of titanium and its alloys [9-12], particularly when the passivated wire surfaces break because of mechanical friction between brackets and wires.

To date, there are no combined in-vitro and in-situ studies comparing the effects of fluoride on different orthodontic wires and their frictional resistance. Therefore, the aim of this study was to investigate the effect of topical fluoride on the surface properties of beta-titanium and stainless-steel wires by scanning electron microscope (SEM), and to evaluate the friction resistance of beta-titanium wires and stainless-steel wires to ceramic brackets before/after application of fluoride. The null hypothesis in this study is that the fluoride application will significantly affect the friction resistance and the surface properties of the arch-wires tested in the current study.

Materials and Methods

Two types of orthodontic wires; Stainless-steel alloy TruChrome Resilient archwire (RMO, Inc. Denver, Colorado. USA); and preformed beta-titanium Bendaloy Nickel Free archwire (RMO,Inc. Denver, Colorado. USA) with a cross section of 019 x 0.025 inch were investigated. 50 central incisor ceramic brackets standard edgewise (No built in torque or tip) (Signature III, RMO,Inc. Denver, Colorado. USA) with slots size 0.022 x 0.028-inch were used in this study. (Figure 1) shows summary for the experimental groups.

In this study 20 stainless-steel alloy and 20 beta-titanium archwires were used. The topical fluoride agent used was Acidulated phosphate fluoride (Nupro APF) 1.23% NaF, pH 3.9. (Dentsply International, York, USA). All wire specimens were immersed in fluoride gel for 1 hour [11]. Half of the fluoride treated wires were examined by SEM while the remaining wires from each group were tested for their friction coefficient and then examined by SEM.

Informed consents were obtained from all the participants of the study and the protocol was approved by the ethical committee of the faculty of Dentistry. Twenty orthodontic patients attending the Department of Orthodontics clinic, Faculty of Dentistry, King AbdulAziz University. wearing full bonded fixed orthodontic appliance were selected according to the following criteria:

All patients were young adult females with permanent dentition ranging from 12-18 years old.

- All patients had their teeth leveled and aligned.

- Each patient had a fixed orthodontic appliance with standard edgewise ceramic brackets (RMO, Inc. Denver, Colorado. USA.).

- Brackets were bonded with no-mix chemical curing bonding resin (Reliance Orthodontics products, Inc).

- Good oral hygiene instructions were given to all patients.

The stainless-steel and beta-titanium archwires were left passive inside the patient mouth for 3 weeks. Then they were collected with sterile instruments. Half of the fluoride treated wires were examined by SEM while the remaining wires from each type group were tested for their friction coefficient and then examined by SEM.

A total of 50 ivory central incisors were embedded in an acrylic resin block in a metallic mould. 50 Ceramic brackets were bonded on the labial surface of the ivory teeth using a bracket positioner. The universal testing machine (Instron Corporation, Canten Industries, Inc., Florida, USA) was used for measuring the generated frictional force at the bracket-wire interface, by sliding the wire through the bracket slot, under small tangential displacements. The metallic mould was fixed on the universal testing machine. Wires 4 cm long from each group were inserted into the bracket slot.

Elastomeric ligatures (American orthodontics, Sheboygan, USA) were placed over the bracket tie-wings engaging the arch wire. One end of the tested wire was left free, and the other end was attached to the moving upper arm of the universal testing machine with 5-kg load cell.

The tested wire was pulled upward through the bracket slot at a speed of five mm per minute for a minute [3, 13]. The frictional force generated by each wire-bracket assembly was registered in kilograms by the tension load cell. After each test, the mould was removed and a new wire was placed with a new ceramic bracket. Static frictional force was measured as the value of force needed to start wire movement through the bracket slot. This force was measured as the maximal initial moving force on the universal testing machine at one minute intervals of moving wire.

All specimens were examined before and after friction test by SEM (Jeol JSM – 225 – 11- Scanning Microscope, Jeol Ltd., Japan) to determine surface changes on the orthodontic wire after the friction test and the application of fluoride. The wire specimens were examined using the SEM and photomicrographs were taken at a low magnification of x150 and a higher magnification of x500.

The results were recorded and analyzed statistically using paired t-test to compare frictional resistance means of the stainless-steel wires to beta titanium wires in as-received, in-vitro and in-situ experiments (p≤0.05). Dunnett t-test was used to compare the friction coefficient of the control (as-received) wires for each type of wire to their corresponding type of wires after fluoride application either in-vitro or in-situ. All statistical examinations were carried out at a level of significance of (p≤0.05).

Results revealed that the degree of friction generated at the bracket/archwire interface was affected by the type of archwire (p≤0.05). The mean and standard deviation of frictional resistance of the two archwires are summarized in (Figure 2).

Figure 2. Frictional resistance values of tested wires to ceramic brackets in Kg. Connected bars are statistically significant p≤0.05.

t-test showed that there was significant difference between the friction resistances of stainless-steel wires attached to ceramic brackets when compared to the friction resistance of beta-titanium wires attached to ceramic brackets in the as-received,in-vitro and the in-situ experiments (Figure 2).

Dunnett t-test showed that there were no significant differences between the frictional resistance means of all wires` in-vitro and in-situ specimens when compared to their as-recieved specimens (p≤0.05) (Figure 2).

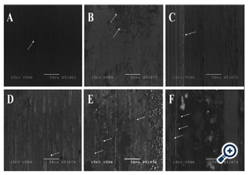

The SEM micrographs of the side surfaces of the two types of wires in the three groups are shown in (Figure 3, 4).

Figure 3. SEM pictures for as-received, in-vitro and in-situ specimens before friction test.

(A) As-received stainless-steel wire showing a smooth surface.

(B) Stainless-steel wire after in-vitro application of fluoride did not show significant defects.

(C) Stainlesssteel wire after in-situ application of fluoride did not show significant defects.

(D) Asreceived beta-titanium wire. White arrows show areas of longitudinal cracks and pits.

(E) Beta-titanium wires after in-vitro application of fluoride. The wire was covered with masses of corrosive products and the surface showed major cracks marked with white arrows.

(F) Beta-titanium after in-situ application of fluoride. White arrows point to numerous areas of longitudinal defects and pits.

Figure 4. SEM pictures for as-received, in-vitro and in-situ specimens after friction test.

(A) As-received stainless-steel wire showing a smooth surface. White arrow points to fine line demarcating line of draw of the wire in ceramic bracket.

(B) Stainless-steel wire after in-vitro application of fluoride. White arrows show line of draw of wire through bracket.

(C) Stainless-steel after in-situ application of fluoride. White arrow shows line of draw of wire through the bracket.

(D) As-received beta-titanium wire. White arrow shows areas of longitudinal cracks, pits and deep line of draw for the wire through ceramic bracket.

(E) Beta-titanium wires after in-vitro application of fluoride, white arrows show major cracks.

(F)Beta-titanium after in-situ application of fluoride. White arrows point to numerous areas of longitudinal defects and pits.

The observed surfaces of the as-received wires showed that stainless- wires exhibited a smooth surface before friction test (Figure 3A). Fine tracks resulting from the draw of stainlesssteel wire after friction were observed (Figure 4A). The as-received betatitanium side surface was rough with many pores, surface defects and corrosion pits produced by the manufacturing process (Figure 3D). After the friction test pits and grooves were observed on the beta-titanium wire surface, along with wear tracks resulting from the friction test (Figure 4D).

The in-vitro application of fluoride exerted detrimental effects on the beta-titanium wires with evident signs of surface corrosion either before or after friction test. Before the friction test fluoride attacked the beta-titanium surface causing numerous grooves and cracks which were associated with generalized corrosion covering the whole surface of the wire (Figure 3E). After the friction test (Figure 4E) generalized roughness and corrosion products together with numerous grooves were observed. However, the stainless-steel wires showed less signs of surface deterioration either before or after the friction test (Figure 3B, 4B).

The application of fluoride in the in-situ experiment affected the surfaces of beta-titanium wires causing the coverage of the wire surfaces with corrosion products (Figure 3F). After friction test beta-titanium wires exhibited peeling of the surface with numerous deep grooves (Figure 4F). The stainless-steel in-situ specimens showed a smooth surface with few pits either before or after the friction test (Figure 3C, 4C).

Discussion

Fluoride application has an important role in the caries control process however; the interaction of fluoride with orthodontic titanium wires should be taken into consideration during the orthodontic treatment. In the current study, fluoride was applied for the first time on the orthodontic wires inside the patients’ mouths and then retrieved to verify the exact effect of fluoride on the beta titanium wires. Fluoride application affected the surface properties of the beta titanium wires; however, it did not affect the friction resistance of the beta-titanium archwires or the stainless-steel arch-wires to ceramic brackets. The null hypothesis adopted in this study was partially accepted.

All wires used in this study were rectangular wires because these types of wires offer control in all three planes [14, 15]. The acidulated phosphate fluoride gel used in the current study has an approximate concentration of 10,000 part per million of fluoride with an acidic pH of 3.9 due to its documented effect on preventing caries. The fluoride agent was applied in-vitro and in-situ to observe its effect on the tested wires [16, 17].

The selected duration of fluoride application in the in-situ study was according to the manufacturer’s instructions. The duration of fluoride application in the in-vitro study was 60 minutes which corresponds to 21 days of daily tooth brushing which is equivalent to average follow up period during orthodontic treatment [11]

In the in-situ experiment all patients had their teeth leveled and aligned with the wires placed with no force applied on them to avoid any frictional forces exerted from the brackets.

Beta-titanium arch-wires recorded significantly high coefficient of friction when compared to stainless-steel wires in the as-received, in-vitro and in-situ experiments. These results may be attributed to the rough surfaces observed in the beta-titanium wires by SEM in the current study.

This agrees with many studies documenting the direct relation between the increase of surface roughness and the increase of friction resistance [6, 13, 18-21].

The observed beta-titanium rough surface for the as-received wires was probably due to the complex manufacturing process of the beta-titanium wires [22].

On the other hand, stainless-steel as-received wires exhibited a smooth surface with the existence of very few scratches and minute pits which may be due to the polishing of the wire during its manufacturing.

The SEM pictures of the two types of wires after one hour of topical fluoride immersion (invitro experiment) showed the different responses of the wire surfaces to this challenge due to the difference in corrosion behavior between the two wires. Stainlesssteel wires corrosion resistance is ascribed mainly to the presence of Cr2O3 in the passive film formed on its surface. On the other hand, the corrosion behavior of the titanium containing alloys depends on an oxide film composed of mainly titanium oxide on the surface, which spontaneously covers the surface of titanium and its alloys in the presence of oxygen.

It is speculated that in the in-vitro current experiment stainlesssteel wires exhibited the least changes on its surface, due to the stability of the protective Cr2O3 layer formed on its surface [23]. However, the beta-titanium wires exhibited a deteriorating surface when exposed to the acidulated fluoride topical agent which suggests that the titanium oxide protective layer was destroyed due to the attack of the fluoride ions in addition to the acidic medium of the topical fluoride agent, allowing the process of hydrogen embrittlment to take place [24].

There are some considerations that must be taken when interpreting the results of the in-vitro friction experiment and comparing it to the in-situ experiment results. This may be explained by the fact that when an orthodontic wire is exposed to the oral environment, a non cellular acquired biofilm is rapidly organized on the material surface by spontaneous adsorption of extracellular macromolecules composed of glycoproteins and proteoglycans. The formation of biofilm is followed by a modification of wire surface properties. The outcome of the biofilm adsorption depends on the biological fluid flow rate at the site of contact, the type of interfacial interactions involved, and the attachment strength with substrate. In the oral cavity some precipitation of calcific biofilm and formation of micro particles on the slot wall and wire surfaces may occur. These precipitations might either reduce the coefficient of friction by producing a boundary lubrication effect (i.e. through salivary protein adsorption and plaque accumulation). Alternatively, calcified integuments might increase the surface roughness and friction resistance [25].

However, the in-situ current experiment showed the same deteriorating effects for the surface properties of beta-titanium wires in the in-vitro experiment after fluoride application which suggests that saliva buffering effect on the fluoride applied in-situ was not enough to overcome the negative effect of fluoride on beta-titanium wires [17].

A previous study 26 showed severe deterioration of the Nickel Titanium wires friction resistance to ceramic brackets tested in-vitro after topical fluoride application, while, the in-situ results did not show significant increase in friction resistance of Nickel Titanium wires to ceramic brackets exposed to a similar topical fluoride application challenges. The aforementioned mentioned results and the results obtained from the current experiment confirm the importance of conducting both in-vitro studies and comparing it to the in-situ results.

Further research is needed to investigate the exact biological effect of the released ions from corrosion process of the titanium containing wires on the oral environment.

Conclusion

In the present study, as-received beta-titanium wires showed roughness of their surfaces and significant increased friction to ceramic brackets when compared to stainless-steel wires. Moreover, application of topical fluoride caused deterioration of surface properties of betatitanium wires. Therefore, it is highly recommended to take into consideration the high friction resistance of beta-titanium arch-wires to ceramic brackets when planning the suitable forces or durations exerted by beta-titanium arch-wires during orthodontic treatment.

Acknowledgement

This project was funded by the Deanship of Scientific Research (DSR), King Abdulaziz University (KAU), Jeddah, under grant No. (1433/165/341). The authors, therefore, acknowledge with tanks DSR technical and financial support.

References

- Bishara SE, Olsen ME, VonWald L, Jakobsen JR (1999) Comparison of the debonding characteristics of two innovative ceramic bracket designs. Am J Orthod Dentofacial Orthop 116(1):86-92.

- Fidalgo TK, Pithon MM, Maciel JV, Bolognese AM (2011) Friction between different wirebracket combinations in artificial saliva--an in vitro evaluation. J Appl Oral Sci 19(1):57-62.

- Guerrero AP, Guariza Filho O, Tanaka O, Camargo ES, Vieira S (2010) Evaluation of frictional forces between ceramic brackets and archwires of different alloys compared with metal brackets. Braz Oral Res 24(1):40-45.

- Nishio C, daMotta AF, Elias CN, Mucha JN (2004) In vitro evaluation of frictional forces between archwires and ceramic brackets. Am J Orthod Dentofacial Orthop 125(1):56-64.

- Keith O, Jones SP, Davies EH (1993) The influence of bracket material, ligation force and wear on frictional resistance of orthodontic brackets. Br J Orthod 20(2):109-115.

- Loftus BP, Artun J, Nicholls JI, Alonzo TA, Stoner JA (1999) Evaluation of friction duliding tooth movement in various bracket-arch wire combinations. Am J Orthod Dentofacial Orthop 116(3):336-345.

- Tanne K, Matsubara S, Hotei Y, Sakuda M, Yoshida M (1994) Frictional forces and surface topography of a new ceramic bracket. Am J Orthod Dentofacial Orthop 106(3):273-278.

- Doshi UH, Bhad-Patil WA (2011) Static frictional force and surface roughness of various bracket and wire combinations. Am J Orthod Dentofacial Orthop139(1):74-79.

- Watanabe I, Watanabe E (2003) Surface changes induced by fluoride prophylactic agents on titanium-based orthodontic wires. Am J Orthod Dentofacial Orthop123(6):653-656.

- Schiff N, Grosgogeat B, Lissac M, Dalard F (2004) Influence of fluoridated mouthwashes on corrosion resistance of orthodontics wires. Biomaterials 25(19):4535-4542.

- Ogawa T, Yokoyama K, Asaoka K, Sakai J (2004) Hydrogen absorption behavior of beta titanium alloy in acid fluoride solutions. Biomaterials 25(12):2419-2425.

- Al-Khatib S, Berradja A, Celis JP, Willems G (2005) In vitro friction of stainless steel arch wire-bracket combinations in air and different aqueous solutions. Orthod Craniofac Res 8(2):96-105.

- Prososki RR, Bagby MD, Erickson LC (1991)Static frictional force and surface roughness of nickel-titanium arch wires. Am J Orthod Dentofacial Orthop100(4):341-348.

- Garner LD, Allai WW, Moore BK. A comparison of frictional forces during simulated canine retraction of a continuous edgewise arch wire. Am J Orthod Dentofacial Orthop 1986;90:199-203.

- Tecco S, Tete S, Festa F (2009) Friction between archwires of different sizes, cross-section andalloy and brackets ligated with low-friction or conventional ligatures. Angle Orthod 79:111-116.

- Kwon YH, Jang CM, Jang JH, Park JH, Kim TH,et al.(2008) Effect of fluoride released from fluoride-containing dental restoratives on NiTi orthodontic wires. Dent Mater J 27(1):133-138.

- Matono Y, Nakagawa M, Matsuya S, Ishikawa K, Terada Y(2006) Corrosion behavior of pure titanium and titanium alloys in various concentrations of Acidulated Phosphate Fluoride (APF) solutions. Dent Mater J 25(1):104- 112.

- Angolkar PV, Kapila S, Duncanson MG, Jr., Nanda RS (1990) Evaluation of friction between ceramic brackets and orthodontic wires of four alloys. Am J Orthod Dentofacial Orthop 98(6):499-506.

- Eliades T, Eliades G, Athanasiou AE, Bradley TG (2000) Surface characterization of retrieved NiTi orthodontic archwires. Eur J Orthod 22(3):317- 326.

- Wichelhaus A, Geserick M, Hibst R, Sander FG (2005) The effect of surface treatment and clinical use on friction in NiTi orthodontic wires. Dent Mater 21(10):938-945.

- Burrow SJ (2009) Friction and resistance to sliding in orthodontics: a critical review. Am J Orthod Dentofacial Orthop 135(4):442-447.

- Kaneko K, Yokoyama K, Moriyama K, Asaoka K, Sakai J (2004) Degradation in performanceof orthodontic wires caused by hydrogen absorption during short-term immersion in 2.0% acidulated phosphate fluoride solution. Angle Orthod 74:487-495.

- Huang HH (2003) Corrosion resistance of stressed NiTi and stainless steel orthodontic wires in acid artificial saliva. J Biomed Mater ResA 66(4):829- 839.

- Yokoyama K, Kaneko K, Moriyama K, Asaoka K, Sakai J, et al. (2003) Hydrogen embrittlement of Ni-Ti superelastic alloy in fluoride solution. J Biomed Mater ResA 65(2):182-187.

- Eliades T, Bourauel C (2005) Intraoral aging of orthodontic materials: the picture we miss and its clinical relevance. Am J Orthod Dentofacial Orthop 127(4):403-412.

- Abbassy MA, Bakry AS (2013) Fluoride influences titanium orthodontic wires` surface texture and friction resistance. International Association Dental Research /AADR/CADR General Session and Exhibition.